Important Point

What Are Tyre Sizes?

The vehicle tyre size is related to the width and height of the rubber your car is wearing, as well as the maximum speed at which you are allowed to travel.

Although the numbers are on the sidewalk, few people know how to interpret them.

In the fuel filler door, inside the doors panels on the pillar, or sometimes in the glove box, you should find a car tyre sizes list that shows the individual tyre pressures for a single occupant, fully loaded and sustained high speed – that is, for the tyre.

Your car will also give a size limit. It will also be in the manual, but specifications may vary, and with used cars, you may have aftermarket wheels.

As a rule, if you are unsure of your tyre pressures on aftermarket wheels & tyres, around 30 to 35 psi is a safe limit.

Make sure they are the same on both sides of the car, but some cars use different pressure for the front and rear.

If in doubt, contact your manufacturer or tyre specialist.

Also, Read: What Is a Clamp Used? | How Does a Clamp Work? | 38 Different Types of Clamps

Tyre Size Explained

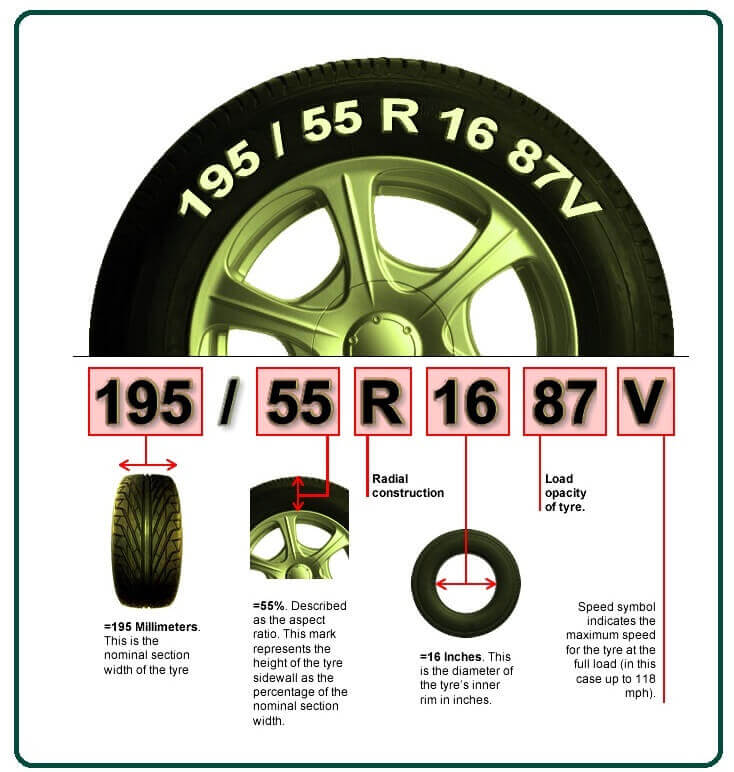

In simple words, the tyre size pattern on any modern car will almost always follow this pattern: above, we have an image of typical tyre size – 195/55 R16 87V

The numbers always break down as follows:

- 195: The width of the tyre is mm. Typically, the higher the numbers, the more grip you get. But not always!

- 55: Tyre profile. By this, we mean the height of the pavement expressed as a percentage of the width. So it will be 97.5 mm high. The lower the profiles, the less the tyre will deform under sideways force, such as cornering, which is good for operation on performance cars. However, it also means there’s less cushioning between the wheel rim and the road, so low-profile tyres are really only an upgrade if you want to prioritize comfortable handling.

- R: Stands for a radial tyre. Before the invention of radial tyres, older cars often used a different construction of reinforcement material, known as crossplay. These days it is unlikely that you will find these tyres except in historical or specialist applications, and road cars all use radial tyres.

- 16: The diameter of a road wheel is expressed in inches.

- 87: This is the load rating of the tyre. The higher the number, the more load each tyre will be able to bear. In this example, 87 would equal 615kg. Multiply that figure by four, and you’ll have an idea of the total weight of your car.

- V: Speed rating. Then, the higher the letter, the faster your car will be able to travel safely. In this case, the tyre has a guarantee of up to 149mph. A table of speed ratings is given below.

Also, Read: What Are Tin Snips? | Different Types | Types of Tin Snips

Useful Article For You

- What Is a Cvt Transmission

- What Is Welding

- What Is Earthing

- What Is a Transformer

- What Is Transmission

- What Is a Pulley

- What Is an Inverter

- What Is Fluid

- What Is a Flywheel

- What Is a Head Gasket

- What Is Composite

- What Is an Alternator

- What Is a Lathe

- What Is a Spark Plug

- What Is a Strut

- What Is a Boiler

- What Is a Torque Converter

- What Is Milling

- What Is a Map Sensor

- What Is a Radiator

- What Is Tlc in a Car

- What Is a Jig

- What Is a Bolt

- What Is a Screw

- What Is Thermal Pollution

- What Is Annealing

- What Is a Turret

- What Is a Turbine

- What Is a Wheel

- What Is Egr

- What Is a Plane

- What Is a Generator

- What Is a Crankshaft

- What Is a Solar Panel

- What Is a Rack and Pinion

- What Is Coupling

- What Is a Shaft

- What Is an Engine

- What Is a Spread Footing

- What Is a Pitched Roof

- What Is Turbo

- What Is a Condenser

- What Is a Motor Mount

- What Is a Fastener

Classification of Tyres

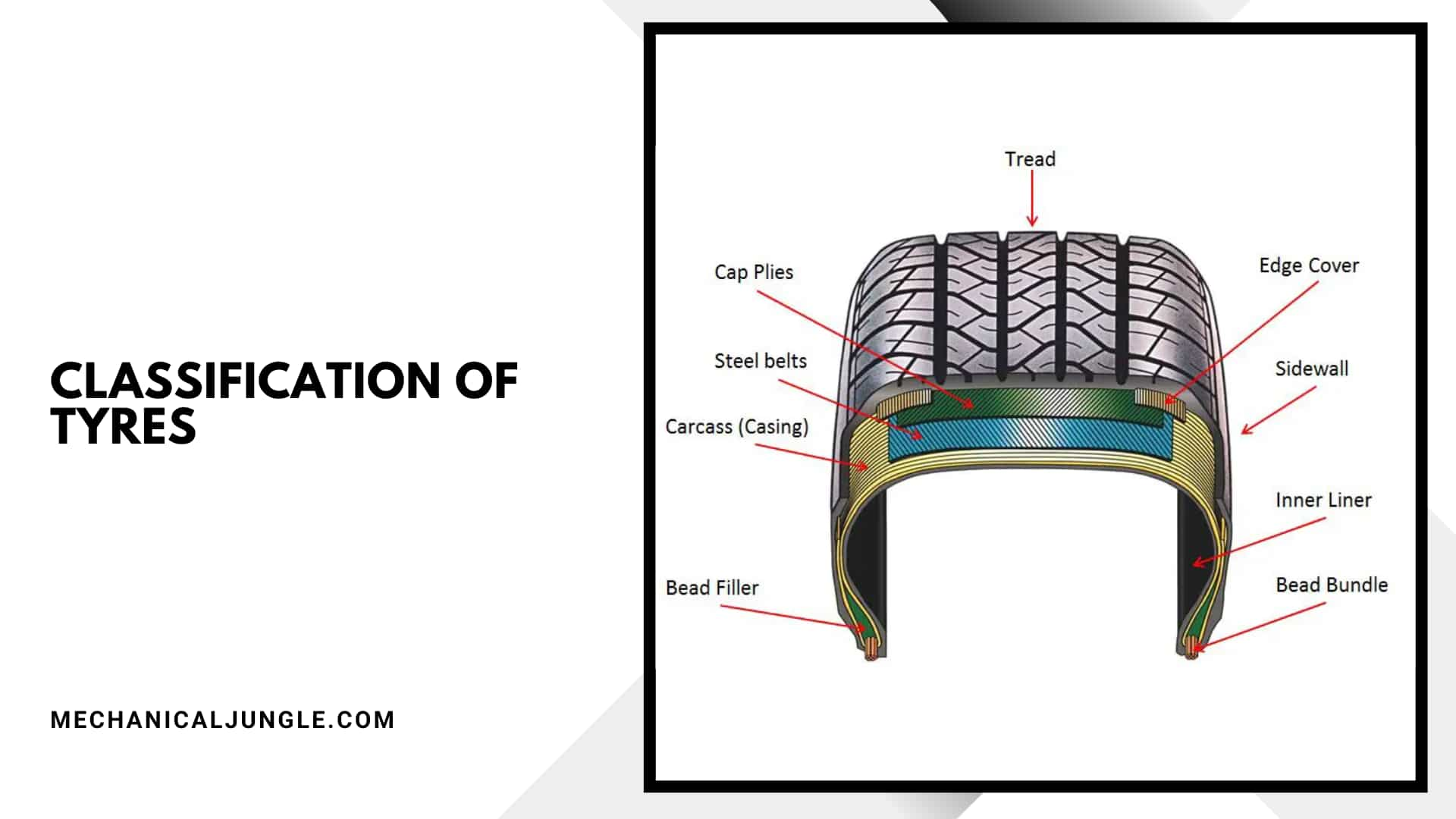

1. Tread

The part of the tyre that actually comes into direct contact with the road surface is called the tread.

It is a composite/rubber compound or a thicker rubber that is formulated to supply a suitable level of traction that does not wear out quickly.

You can see different tread patterns on tyres; these patterns are called tread patterns for each tyre tread.

These tread patterns at discrete frequencies reduce noise levels by featuring a non-uniform (or non-symmetric) lug shape through the circumference of the radial tyre.

2. Bead

This part of the tyre contacts the rim of the wheel of the vehicle.

This bead is usually rigid with steel wire and also made of high-strength low ductility rubber.

It also ensures that a tubeless tyre holds air tightly without any leakage. It does this by sitting tightly against the two rims on the wheel of the vehicle.

3. Sidewall

In a typical tyre structure, you will see a part that bridges the tread and the bead. This part of the bridge is called the footpath.

It is a part that is mostly rubber but also reinforced with steel cords or fabric, which provides flexibility and tensile strength.

4. Shoulder

The part of the tyre that is at the edge of the tread as the structure transitions to the sidewall is called the shoulder.

5. Ply

As a response to the internal pressure in the tyre, the rubber can begin to stretch and lose its shape. This is why plies (singular: ply) are comparatively layers of unbroken cords.

Useful Article For You

- Water Pump Car

- Screw Jack

- Car Shaking When Idle

- Beater Car

- Service Battery Charging System

- Types of Hammers

- Resonator Delete

- Rivet Definition

- Coolant Leak Repair Cost

- 6.0 Vortec

- Battery Saver Active

- File Tool

- Best Head Gasket Sealer

- Cheapest Place to Get Brakes Done

- Tire Feathering

- Ecm Motor

- Service Stabilitrak Chevy Cruze

- Nut Vs Bolt

- Welding Positions

- Ship Engine

- Interstate Car Battery

- Hvac System Diagram

- Keyless Remote Battery Low

- What Is a Girder

- Headliner in Car

- Alternator Vs Generator

- Axle Seal Leak

- What Is Cast Iron

- Car with Lock Symbol

- Vehicle Services Division Letter

- Woodruff Key

- What Is an Automobile

- How Does a Magneto Work

- What Is Hydropower

- What Is a Misfire

- Automobile Engineering

- What Is Arc Welding

- Flight of Stairs

- Types of Cranes

- Cam and Follower

- Disc Brakes Work By

- Shaded Pole Motor

- Mechanical Engineering Companies

- Cv Joint Noise When Driving Straight

Types of Tyres:

1. Categories Tyre

Standard car tyres usually have symmetrical patterns throughout the tread.

However, some high-performance cars have tyre with special tread patterns.

These asymmetric and directional tyres must be properly fitted to the wheel. Incorrect fitting of both is one of the reasons for MOT failure.

2. Asymmetric Tyres

Asymmetric tyres have different tread patterns on the inner and outer edges of the tread to improve performance.

On the outside edge, the large hard tread blocks help with cornering. On the inside edges, smaller tread blocks are designed to move water and improve wet grip.

There is often a continuous rib in the middle of the walk to help with straight-line stability.

The words ‘inside’ and ‘outside’ on the tyre sidewall indicate which side the tyre should be mounted on.

3. Directional Tyres

Directional tyres are designed to rotate only in one direction, indicated by an arrow on the tyre sidewall.

These tyres are better at dispersing the water that gets accumulated in the front of the tyre. They also reduce road noise and improve directionals stability.

4. Winter Tyres

Their design provides better traction on snow and ice than summer tyres of the same vehicle. Winter tyres are designed to fit and run well on icy surfaces during the winter season.

At temperatures below 7 °C, the rubber in normal tyres begins to harden, reducing grip on cold, wet roads, snow, and ice.

In contrast, winter tyres remain soft and flexible at low temperatures.

They maintain grip, and with the help of several special grooves in the tread called sips, they provide superior braking, handling, and traction in all winter driving conditions.

A typical summer tyre might have around 200 sips, compared to a winter tyre with about 1500.

According to tyre Safe, winter tyres can provide up to 60% better grip in cold conditions and reduce braking distance by up to six full car lengths. It can make a big difference in terms of road safety.

5. All-Season Tyres

Winter tyres are not mandatory in these countries. In many parts of the country, their use can hardly be justified. In mores remotes areas, where winters really take hold, they make sense.

Whether or not to fit winters tyres is an individual decision based on a number of factors – the risk of inclement weather, driving ability, and confidence on snow and ice.

Winter tyres are not suitable for use all year round. Summer tyres give betters performances when temperatures are high and the roads are dry, so you’ll need two sets of tyres. Winter tyres should fit in sets of fours.

Fitting only one pair will affect the balances & stability of the car. An alternative to winter tyres is all-season tyres.

These have high silica contents for low-temperature flexibility & a treads pattern somewhere between that of a normal summer tyre & a winter tyre.

They are rarely as good as specialists tyre but perform better than summer tyres on winter roads and avoid the hassle and cost of swapping wheels and tyres twice a year.

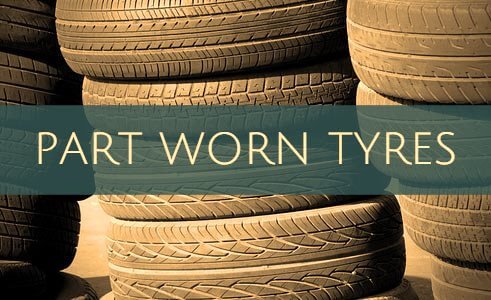

6. Part Worn Tyres

When changing tyres, the safest option is to opt for new tyres. Part-wear tyres can be fitted but must meet various criteria.

The Motor Vehicle Tyres Safety Regulation 1994 has laid down minimum safety standards for the supply of part-wear tyres.

Under regulations, part-worn tyres except retreads must have an EC approval mark and a speed and load capacity index molded into the sidewalls at the time of manufacture.

In addition, all types of part-worn tyres must be marked ‘part-worn in capital letters at least 4 mm high.

Also, Read: What Are Impact Sockets | Reviews of Impact Socket | Accessories of Impact Socket

7. Temporary Tyres

Many automakers today supply their new cars with non-standard spare wheels and tyres.

It is lighter and thinner than usual to save weight and space. For this reason, there is a maximum speed limit when using it – usually 50mph.

Space-saving wheels are intended for emergency purposes & should only be used as temporary measures.

Motorists should be advised to get the originals car tyre repaired or replaced as soon as possibles.

8. Standard Tyres

Also knowns as stock tyres or generals, use tyres; these are usually the OE fitted tyres that you get with the car. The same specification tyres are available in the aftermarket as well.

If you are satisfied with your currents tyre performance & your expectations from the tyres are not too demanding, then these tyres are for you.

Since these are tested & approved by OE manufacturers, most of the performance parameters are optimized for general use. These tyres usually do not tax your pocket as much as premium tyres.

9. Touring Tyres

The main emphasis of these tyres is on comfort. Comfort not only stands for driving comfort low vibration but also reduces the noise level.

Such premium tyres are generally preferred by people using premium cars mainly for going to an office or traveling with family.

Touring tyres’ tread patterns are less aggressive than sporty tyres and have some design features that produce less noise.

Touring tyres can have asymmetric patterns in the top range, and even the asymmetric construction can vary between outer and inner sides.

10. Sporty Tyres

Also known as performance tyres, these designed to improve the grip and handling of the vehicle are referred to as performance tyre.

Made of soft tread composite rubber, they are designed to deliver maximum grip at high speeds, especially during dry and wet weather conditions.

Most sports cars come with these superior performance tires fitted standard to improve their handling & cornering ability.

These tyres are also available in the aftermarkets for drivers who want better handling & performance from their vehicles.

In fact, for those who use their vehicle in tarmac-based motorsport applications, a sporty tyre is the cheapest and most preferred way to reduce lap times.

These tyres usually come with an aggressive tread pattern compared to standard and touring tyres, which makes them a bit noisier at high speeds.

11. High-Speed Tyres

High-speed tyres are available in touring and sporty patterns. Their construction is more durable due to high-speed rolling resistance than resisting high temperatures and handling strong g forces under hard cornering.

Manufacturers often use their findings from motorsports applications to create these high-performance tyres for road use.

These high-performance tyres can often be found fitted on sports cars, supercars, and coupes that are capable of higher speeds than standard family sedans.

However, it must be remembered that though the technology exists to achieve speeds in excess of 300 kmph, fitting such tyres in your average hatchback is pointless.

Due to price constraints in new cars, manufacturers often provide tyres that are capable of handling slightly higher speeds than that particular car.

Here is a chart that shows the commonly available tyre speed ratings in india:

| Speed Symbol | Speed Max (Kmph) | Categories |

| Q | 160 | Available in MUV Tyres |

| S | 180 | Available in Standard Tyre |

| T | 190 | |

| H | 210 | Speeds of H & Above are Consider High speeds |

| V | 240 | |

| W | 270 | Available in Premiums Category Tyres & Premiums / Luxury Imported Cars |

| Y | 300 |

12. Eco-Friendly Tyres

It is not just automobiles that have kept pace with the times and increasing environmental pressure to become eco-friendly.

The tyres they ride on have also become more environmentally friendly. Essentially, eco-friendly tyres help reduce fuel consumption by offering minimal rolling resistance.

Low rolling resistance, as the name suggests, is achieved by reducing friction losses in compounding.

Currently, eco-friendly tyres use silica in a tyre compound that allows tyre manufacturers to produce low rolling resistance tyres with adequate grip.

Manufacturers have also focused on optimizing design, contour, compound, and tread patterns and have taken an entirely new approach to all four components of the tyre to achieve both fuel efficiency and optimum grip.

In india, fuel expenditure per year is many times more than the expenditure on tyres.

Hence the savings through eco-friendly tyres are much higher than the premium paid for these tyres.

13. Run-Flat Tyres

These types of tyres have a number of unconventional designs that allow the tyre to run safely at a limited range of speeds without wind.

This type of tyre has a sturdier type of load-supporting sidewalls in its designs.

In another approach to this type of tyre, there is a supporting type of support structure that is fixed to the rim inside the pneumatic tyre, which will bear the load in any event of deflation in the tyre.

With all these advantages, there is also a disadvantage which is; when run-flat tyres get punctured, many of them cannot be repaired.

Although some brands have provisions for such puncture cases with their tyres, they allow repair of a run-flat tyre, and that’s it.

While other brands do not allow any repairs, if there is a puncture, a complete replacement may be the only available option.

Which are embedded in the rubber to help it hold its shape. Pledge orientation plays an important role in tyre’s performance and is one of the major ways tyres are being classified.

Also, Read: How Does a Wood Plane? | Parts of the Wood Plane | Types of Wood Planes

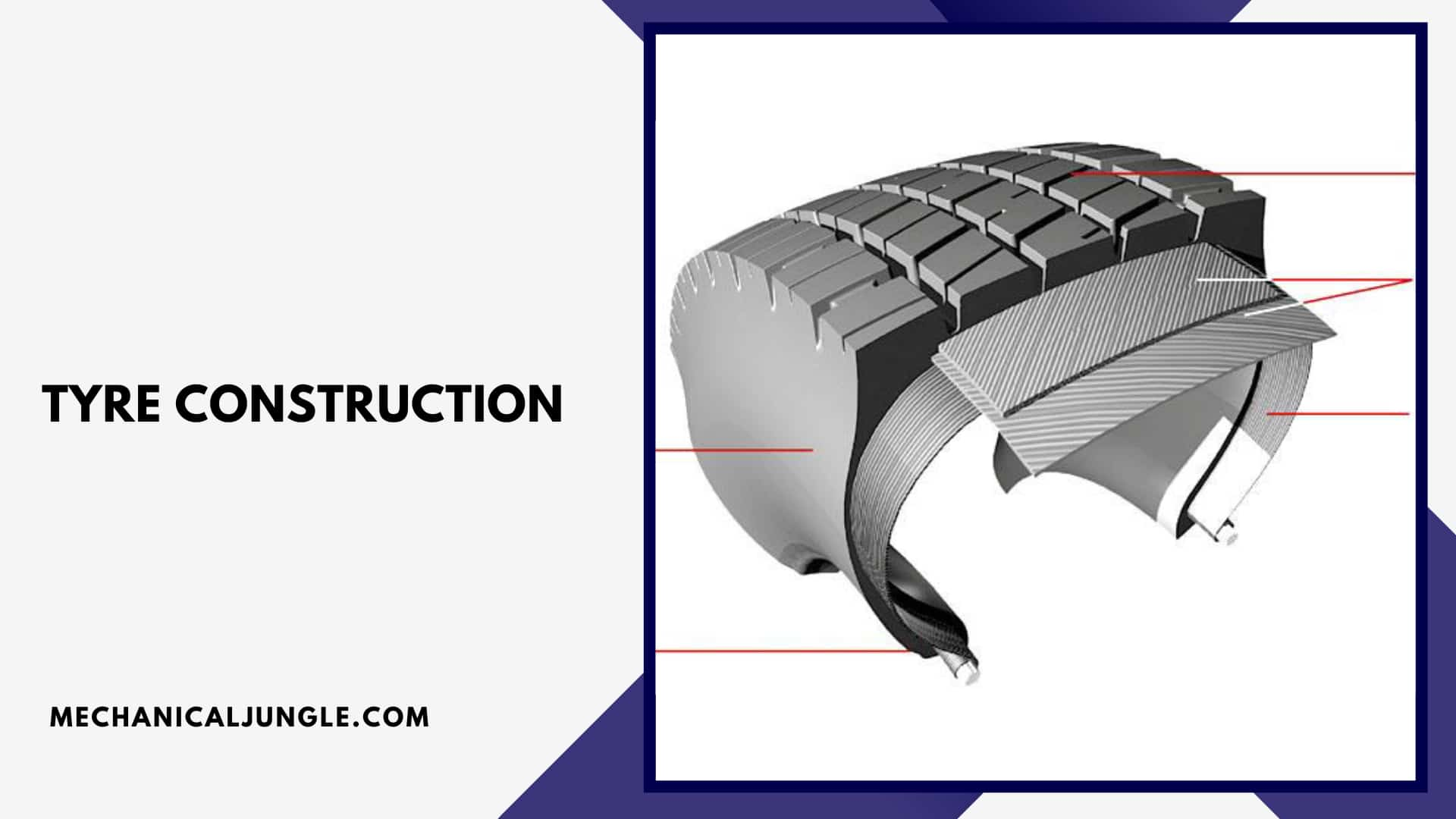

Tyre Construction:

Although the standard design for tyres today is radial tyre technology, there are other types of tyres that are also being used., there are other tyre construction types that are also being used.

Some of these tyre manufacturing types include bias tyres, belt bias tyres, tubeless tyres, semi-pneumatic tyres, airless tyres, solid rubber tyres, and metal tyres used in railway applications.

Bias tyre construction type has increased rolling resistance, reduced traction, and a major loss of control at high speeds when used.

Belted bias construction type is similar to bias type in providing a smooth ride but only reduces rolling resistance due to its belt feature, which increases the rigidity of the tread in its structure.

Radial car tyre types have more advantages than the above two, and some of these benefits include lower rolling resistance, better fuel economy, less blowout, better steering control, and longer tread life.

Frequently Asked Questions (FAQ)

Type of Tyre

- Categories Tyre

- Asymmetric Tyres

- Directional Tyres

- Winter Tyres

- All-Season Tyres

- Part Worn Tyres

- Temporary Tyres

- Standard Tyres

- Touring Tyres

- Sporty Tyres

- High-Speed Tyres

- Eco-Friendly Tyres

- Run-Flat Tyres

Tyre Sizes Explained

205 indicates the normal section width of the tyre in millimeters (205mm). 65 indicates its aspect ratio, a comparison of the tyre’s section height with its section width (65 indicates the height is 65% of its width). R indicates radial ply construction. 15 indicates the nominal diameter of the wheel rim (15 inches).

Classification of Tyres

In general, there are two major classes of tyres, according to the presence or absence of tubes in them. Thus, they are called ‘tubed tyres’ and ‘tubeless tyres’ respectively.

Best Backhoe Tires

Therefore, we have put together a list of the top five things to know before purchasing a new set of backhoe tires.

20.5 X25 Loader Tire

Discover our wide range of tires made for challenging applications and request a quote! Specially designed to meet the requirements for the most severe working conditions.

Firestone Mud Tires

Wherever the trail takes you, Firestone Destination M/T2 tires help grip slick, muddy, and snow-covered surfaces. Made for off-roading, these tires are complete with mud and stone rejector technology and 3-ply sidewall construction. The terrain may be tough, but these tires are tougher.

Agilis Crossclimate

The Michelin® Agilis® CrossClimate® tire offers shorter wet stopping distances and better snow traction than leading competitive commercial tires. SipeLock™ provides hundreds of biting edges for improved wet and snow traction without sacrificing tread block stability.

Like this post? Share it with your friends!

Suggested Read –

- 13 Different Types of Milling Cutters

- Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

- What Is Magneto Ignition System | How Does an Ignition System Work | How Does a Magneto Work | What Does a Magneto Do | Magneto Ignition System

- What Is a Synchromesh Gearbox? | Principle of Synchromesh Gearbox | Construction of Synchromesh Gearbox | Working of Synchromesh Gearbox

- Working of Constant Mesh Gearbox | What Is a Constant Mesh Gearbox? | Different Gear Ratios in Constant Mesh Gearbox | Construction of Constant Mesh Gearbox

- What Is Cupola Furnace? | Cupola Furnace Design । Cupola Construction | Purpose of Cupola | Working Principle of Cupola Furnace: | Advantages of Cupola Furnace | Disadvantages of Cupola Furnace | Applications of Cupola Furnace