Important Point

What Is Magneto Ignition System?

A combustion engine that has some flaming features, such as high speed and high internal compressions, requires a system that produces very high ignitions from spark plugs that are used as a source.

The ignitions system is the system that uses spark plugs as their source where electrical energy input is given to the spark plug.

This article will go into detail about the magneto ignition system, its main parts, functions, benefits, and disadvantages with the application.

There are four types of this ignition system.

- Magneto.

- Distributor.

- Spark Plug.

- Capacitor.

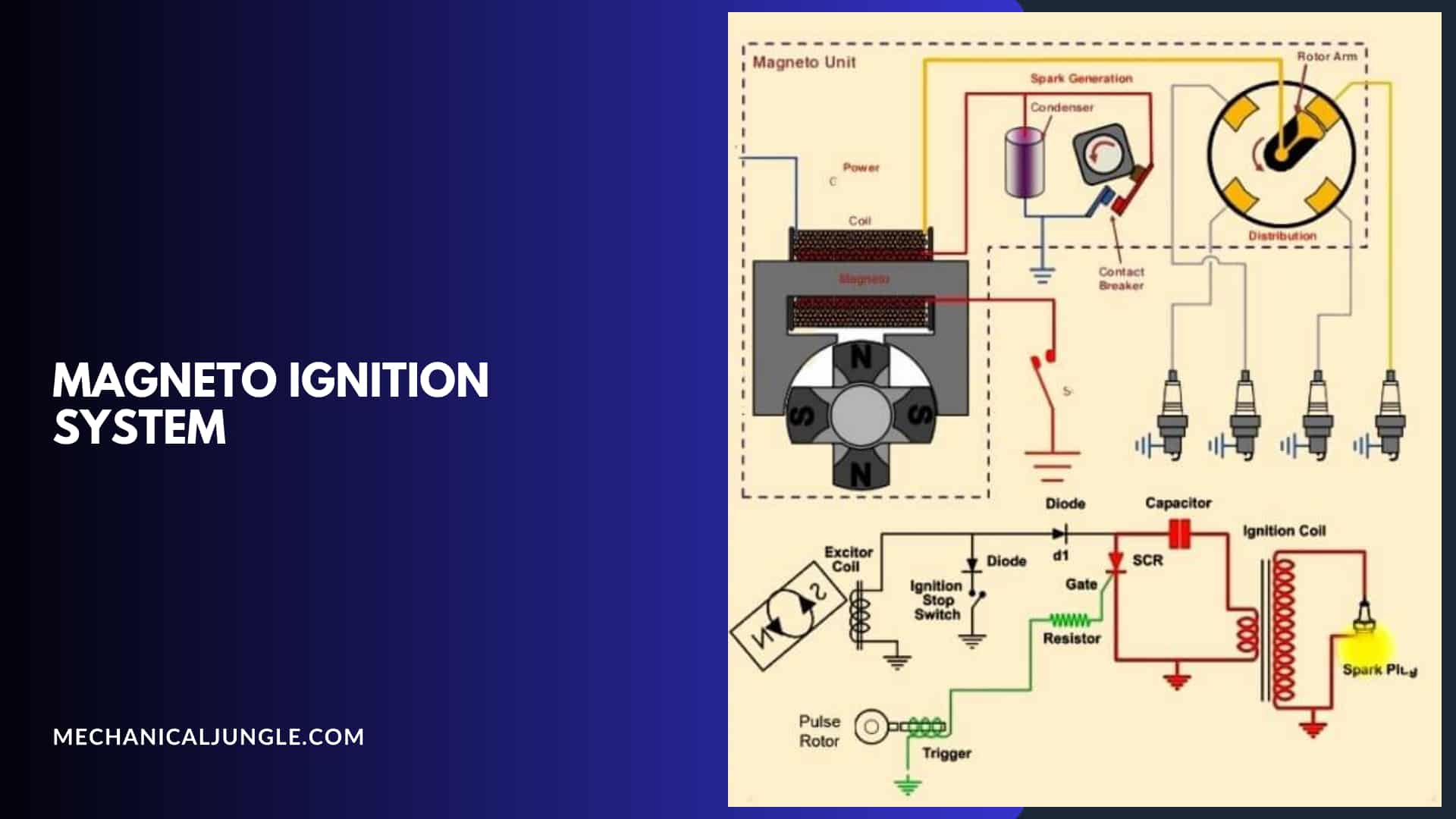

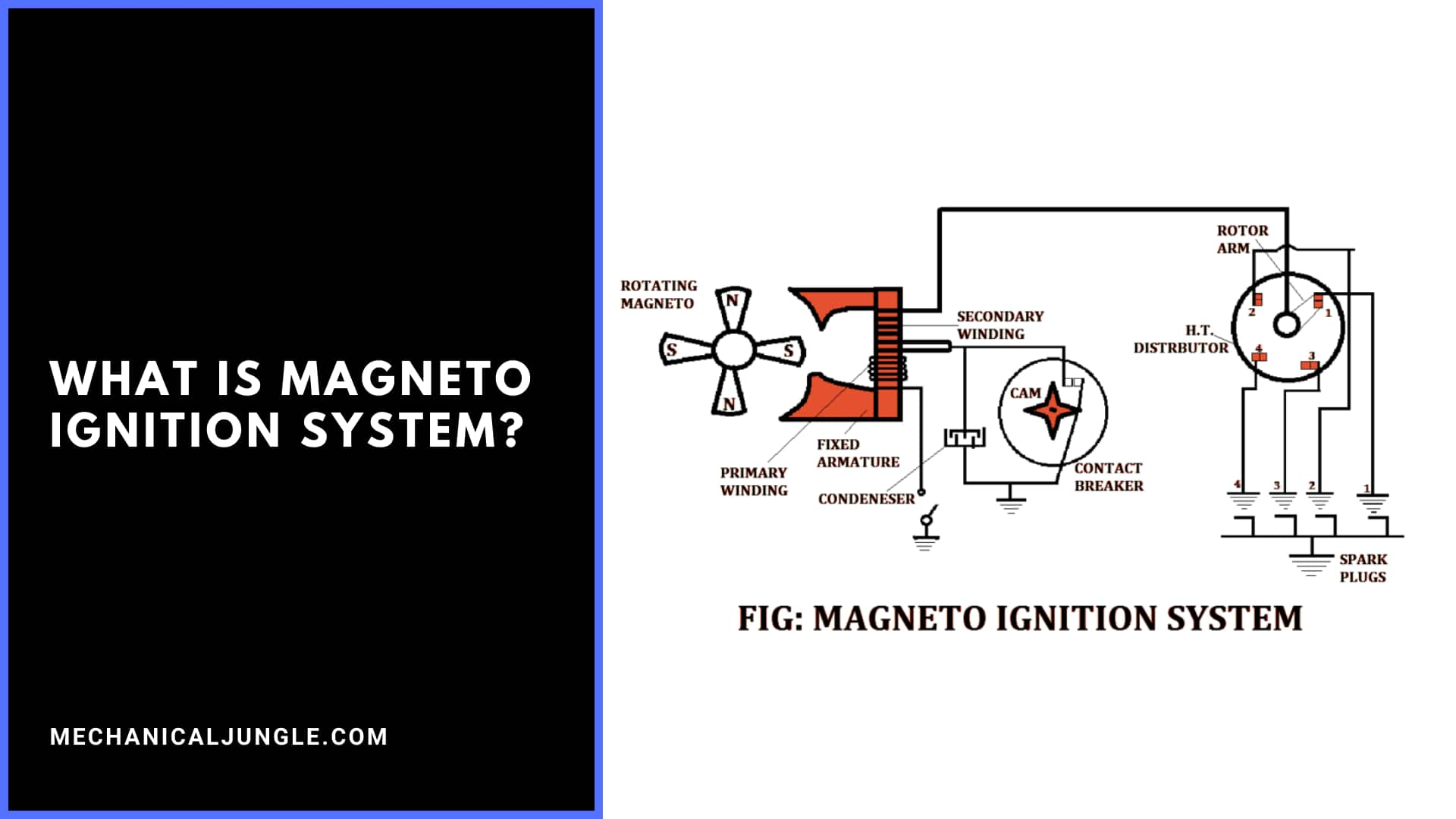

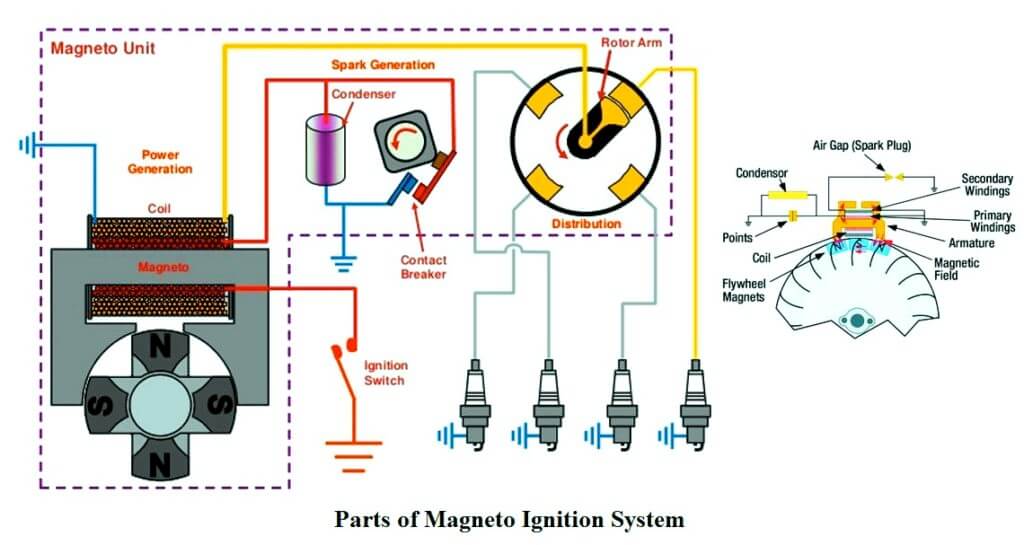

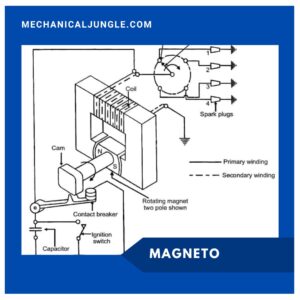

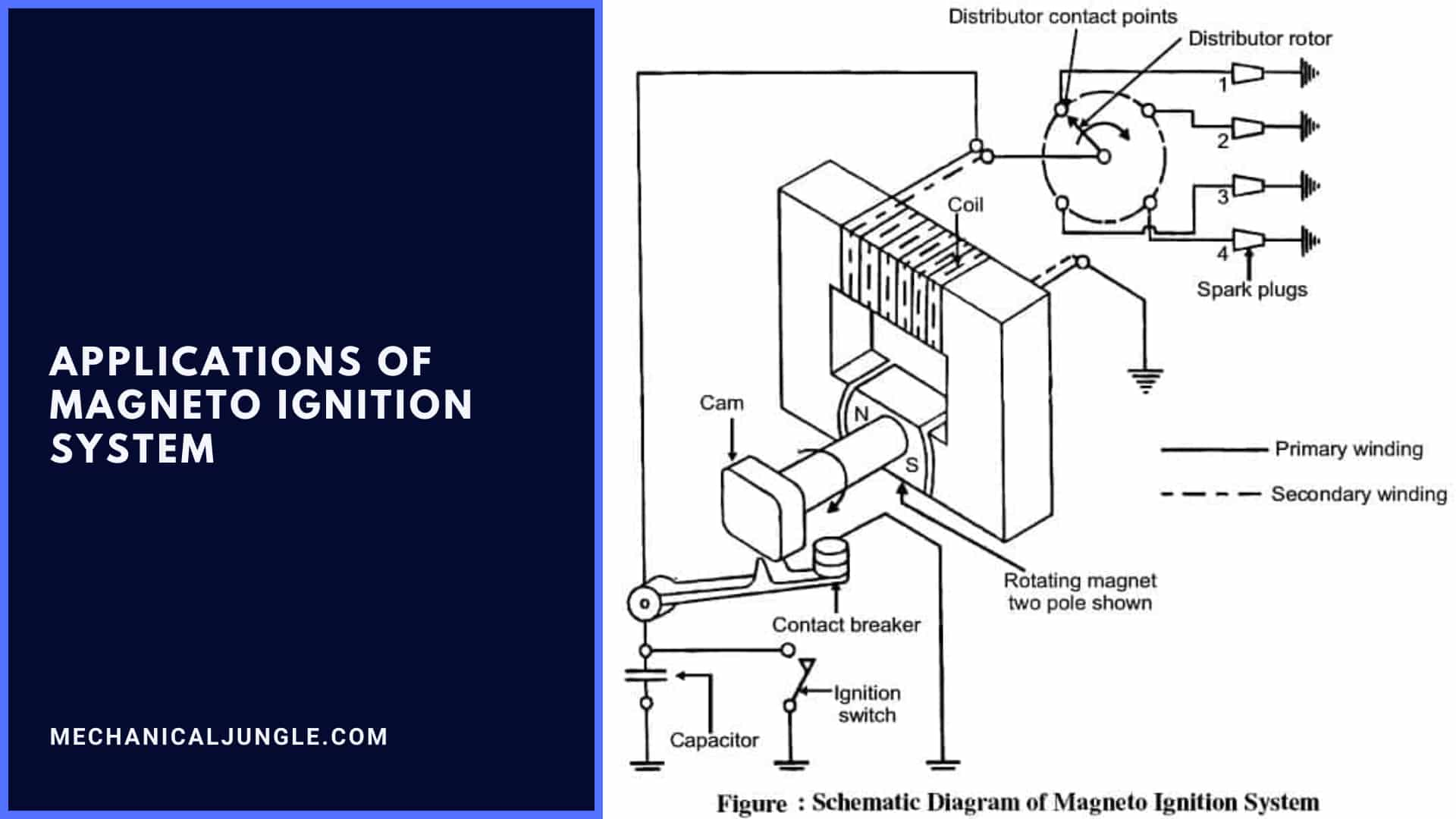

#1. Magneto:

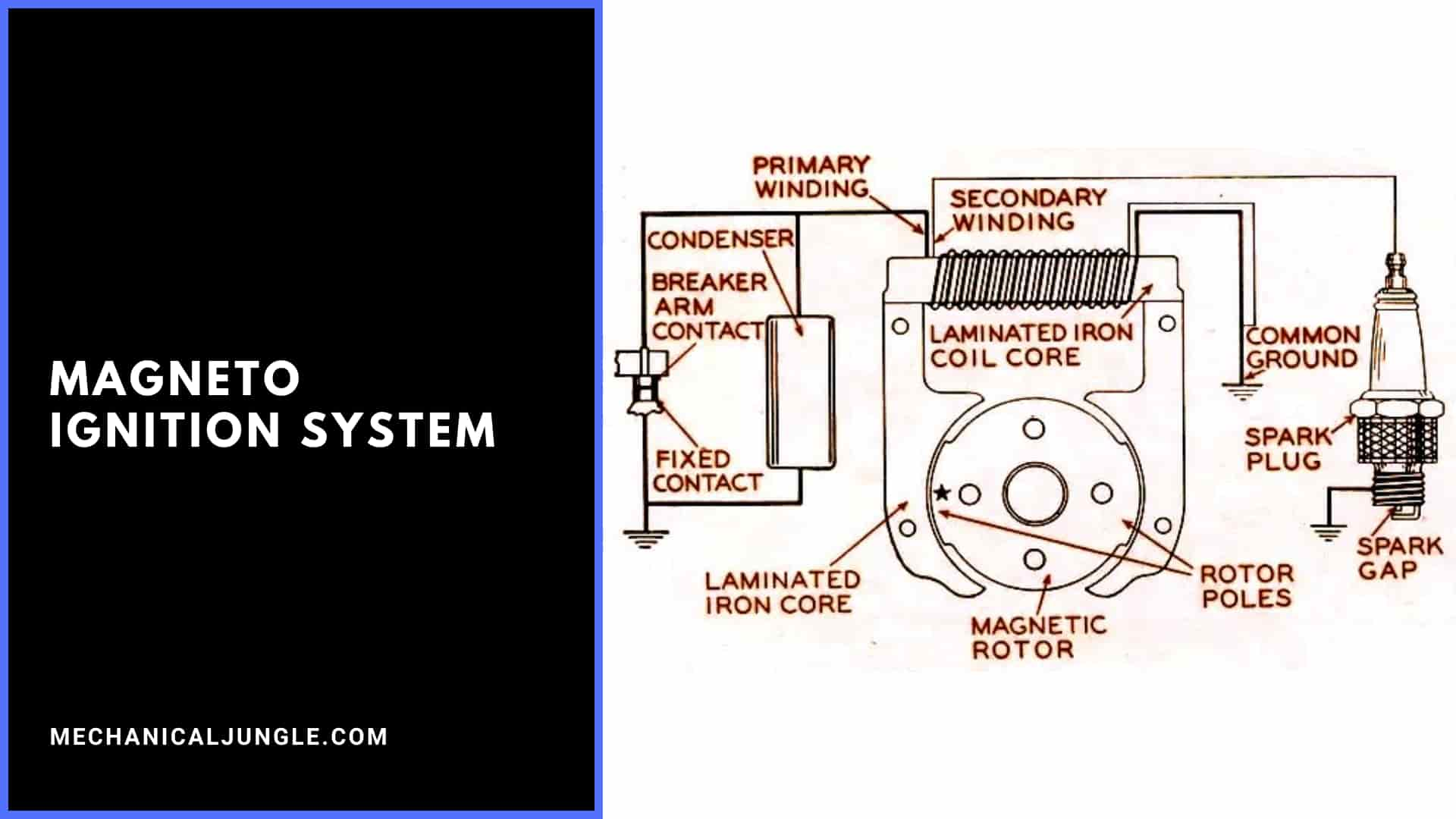

It is a major part of this type of ignition system as it is a source of energy. A magneto is a small electrical generator that is rotated by the engine and is capable of producing very high voltages, and does not require a battery as a source of external power.

The magneto has both primary and secondary windings and thus does not require a separate coil to boost the voltage required to operate the spark plug.

There are two types of the magneto. The first one is known as the rotating armature type, and the other is known as the rotating magnet type.

In the first type, the armatures rotate between stationary magnets. On the other hand, the second type of armature is stationary, and the magnets are moving around the armature.

#2. Distributor:

The distributor is used in multi-cylinder engines to control the sparks in each spark plug in the correct order. This distributes the ignition surge to the individual spark plugs in the correct order.

There are two types of distributors. One is known as carbon brush type and the other as gap type. The carbon brush type is molded by a rotor arm slipping on the metallic segment in a distributor cap or insulating material.

This makes electrical connections or secondary windings with spark plugs. The distributor electrode of the rotor arm is nearby but does not make contact with the distributor cap. Therefore there is no wear of the electrode.

#3. Spark Plug:

Spark plugs typically have two electrodes that are separated from each other. There is a high potential discharge current through it that produces a spark and ignites the combustion mixture in the cylinder.

It mainly consists of two electrodes, a steel shell, and an insulator. The central electrode is connected with the ignition coil supply. It is well insulated with an outer steel shell that is grounded.

There is a small air gap between the steel shell and the central electrode, between which a spark is produced. The electrode is usually made of high nickel alloy so that it can withstand high temperature and corrosion resistance.

#4. Capacitor:

It is a simple electricals capacitor in which two metal plates are separated at a distance by an insulating material. Air is commonly used as an insulating material, but some high-quality insulating materials are used for the special technical requirement.

Also, Read: Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

Working Principle of Magneto Ignition System

- The working principles of this ignition system are the same Except for the working principle of the coil or battery ignition system.

- This is the Magneto that is used to produce energy but not for batteries.

- Here is the following scenario that occurs in it.

- The working principle of the ignition system is similar to Except the working principle of the coil or battery ignition system.

- This is the Magneto that is used to produce energy but not for batteries.

- Here is the following scenario that occurs in it.

- One end of the Magneto is made through a contact breaker, And the ignition capacitor is connected parallel to it.

- The contact breaker is regulated by the cam, and when the breaker is open, Current flows through the condenser and charges it.

- This increases the voltage in the condenser.

- This increases the high voltage in the condenser will act as a Thus the EMF produces a spark through the distributor into the correct spark plug.

- In the initial stage, the engine speed is low, and therefore The voltage generated by the Magneto is low but in the form of rotational speed.

- Engine increases, It also increases the voltage generated Magneto and flow of current have also increased.

- At medium and high speeds, it is more efficient.

- It is more convenient as there is no battery. It requires less maintenance.

- The main advantage of magneto ignition systems over other ignition systems is No external source is needed to generate this energy.

- It was managed under low Stress and high Stress.

- At high Stress, a large amount of voltage is generated using a Step-up transformer that can be used for airplane engines and engines like the following Stress can manage this voltage so that it flows in the smallest part Wiring and also avoid leakage.

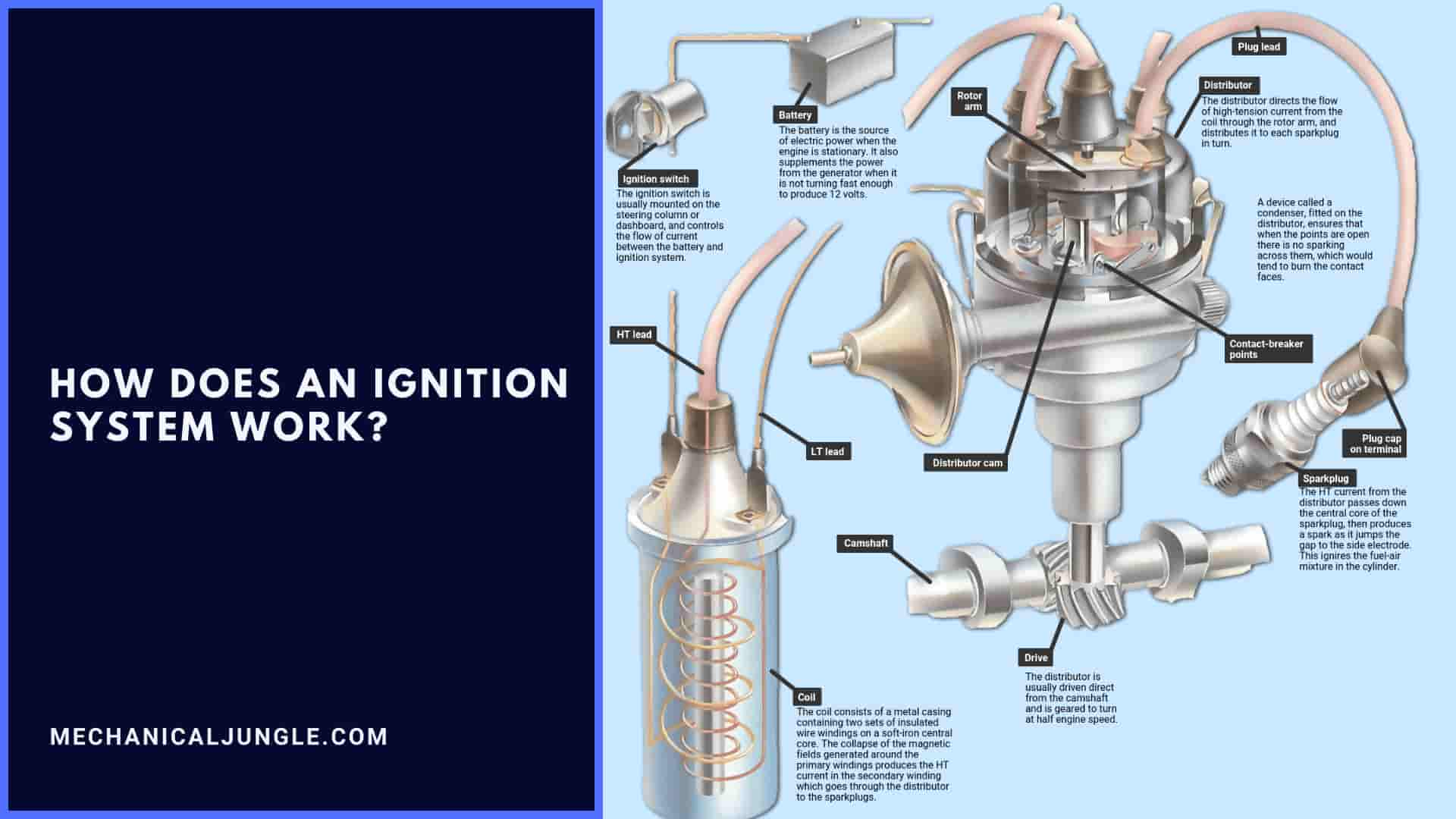

How Does an Ignition System Work:

- The ignition system is intended to generate a much larger volt lifespan from the car’s 12-volt battery and to send each sparkplug in turn, igniting the fuel-air mixture in the engine’s combustion chambers.

- The coils are the component that produces this high voltage.

- It is an electromagnetic device that converts a low tension (LT) current from a battery to a high-tension (HT) current each time the distributor’s contact-breaker point is opened.

- The distributor unit consists of a metals bowl with a central shaft, usually driven by a crankshaft or sometimes by a crankshaft.

- The bowl has a contact-breaker point, rotor arm, and a device for changing the ignition timing. It also carries a distributor cap.

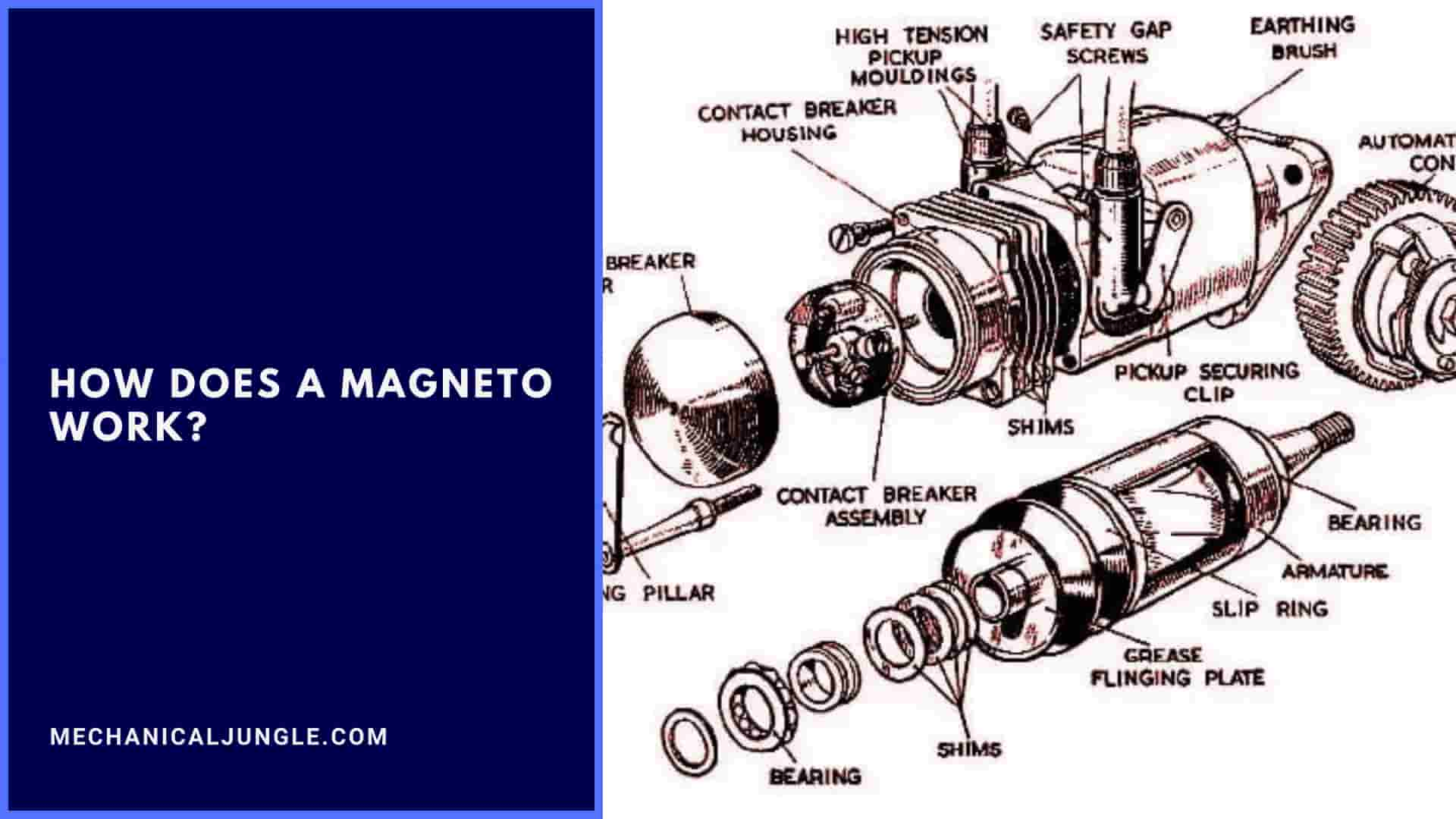

How Does a Magneto Work?

- Most small lawnmowers, chain saws, trimmers, and other small gasoline engines do not require batteries.

- Instead, they generate power for spark plugs using a magneto.

- Magneto is also used on many small airplanes (for example, the Cessna 152 is seen in the work of How Airplane) because they are highly reliable.

- The idea behind any ignition system is to generate an extremely high voltage at exactly the right time – on the order of 20,000 volts.

- The voltage causes a spark to cross the spark plug gap, and the spark ignites the fuel in the engine.

- For details, see how car engines work or how two-stroke engines work.

- The magneto is the white blocks in the following photo (this is the magneto for the series): The idea behind a magneto is simple.

- It is basically an electrical generator tuned to produce a periodic high-voltage pulse instead of a constant current.

- An electric generator (or a magneto) is the reverse of an electromagnet (see How electromagnets work for details).

- Electromagnets consist of a coil of wire around an iron bar (armature).

- When you current the coil of an electromagnet (for example, with a battery), the coil creates a magnetic field in the armature.

- In a generator, you reverse the process.

- You rotate a magnet behind the armature to create an electric current in the coil.

- A magnet consists of five parts: An armor.

- In the magneto above, the armature is shaped like the capital “U.” Two ends of the U point towards the flywheel.

- A primary coil of perhaps 200 turns of coarse wire wrapped around one leg of u A secondary coil of perhaps 20,000 of very thin wire wrapped around the primary coil is rotated A simple electronic control unit commonly known as “electronic ignition” (or a set of breaker points and capacitors)—a pair of strong permanent magnets embedded in the engine flywheel.

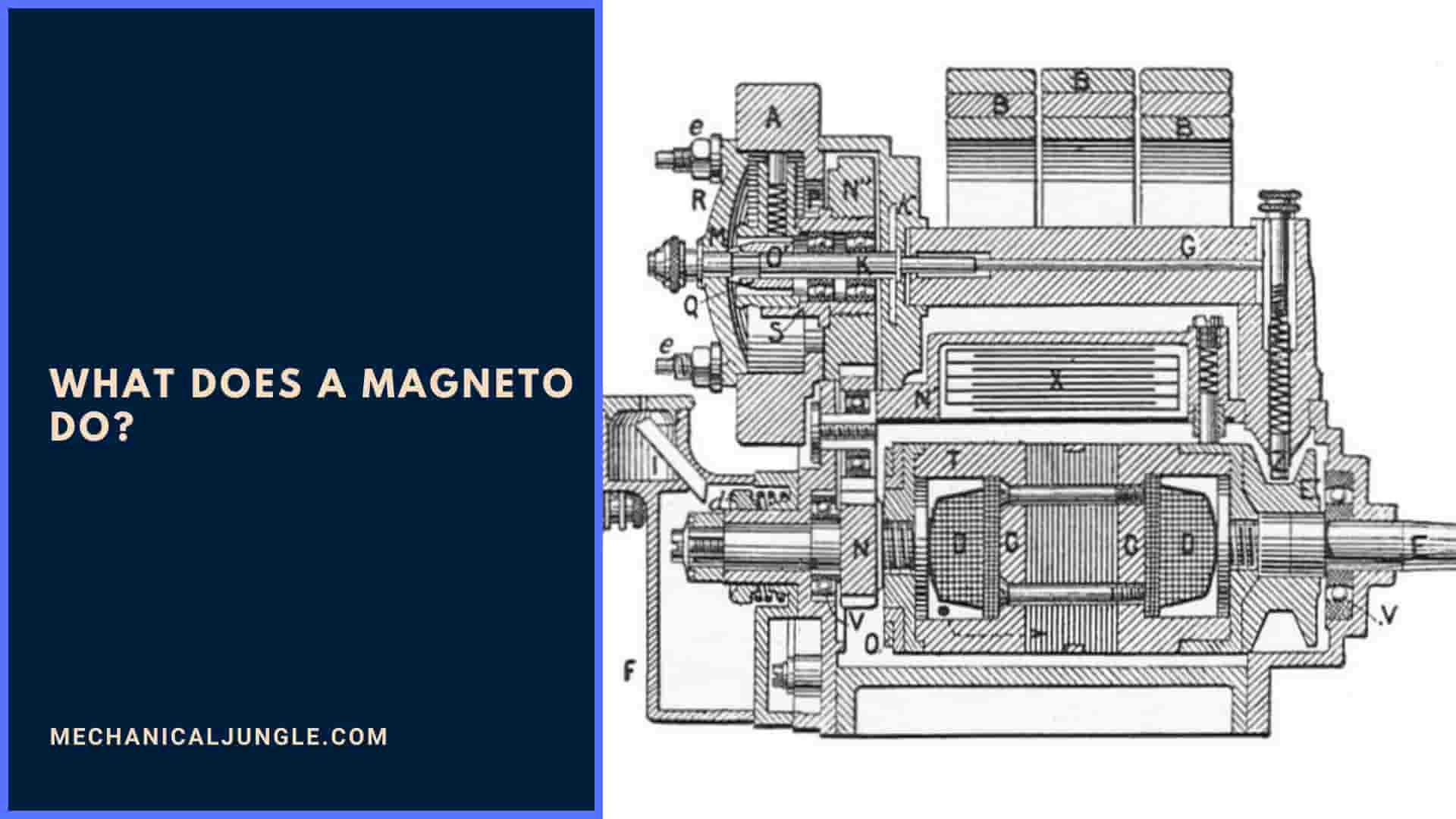

What Does a Magneto Do?

An ignition magneto, or high tension magnetos, is a magneto that provides currents to the ignition system of spark-ignition engines, such as a petrol engine.

This produces high voltage pulses for the spark plugs. The old word stress means voltage. The use of ignition magnetos is now primarily confined to engines where there is no other available power supply, for example, in solutes and chains.

It is also widely used in aviation pistons engines even though a power supply is usually available. In this case, the magneto’s self-propelled operation is assumed to provide increased reliability; In theory, the magnetos should continue operation as long as the engine is operating.

Magneto Ignition System

- Today we will discuss the magneto ignition system.

- In our previous post, we learned about the battery ignition system and how it works, but the magneto ignition system is completely different.

- Magnetos are a special type of ignition system with their own electricals generator to provide the necessary energy for the ignition system.

- This replaces all components of the battery ignition system except the spark plug.

- Today we will do a complete study about this system.

Magneto Function

- The magneto-gravity response function, which shows a phase relationship between an average source body with a constant density-to-magnetization ratio between magnetic and gravitational anomalies, determines the magnetization direction of a source body for 2-D and 3 Is derived from.

- The validity of the method is demonstrated through application to test the -D case data and to remove discrepancies from the ditto ridge.

- The ditto ridge is magnetized in the current main field direction, which is in contrast to the shallow tilt suggested by the study of the Deep Sea Drilling Project (DSDP) sediment core.

- Strong general magnetization is specified for high magnetic susceptibility and/or viscous remanent magnetization.

Also, Read: Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

Applications of Magneto Ignition System

Here is a partial list of applications of equipped engines. Magneto ignition system.

- Tractors, oil burners, and outboard motors

- Airplane Engine

- Power units, marine engines, and natural gas engines

- Washing Machine

- Truck and Cement Mixer

- Buses

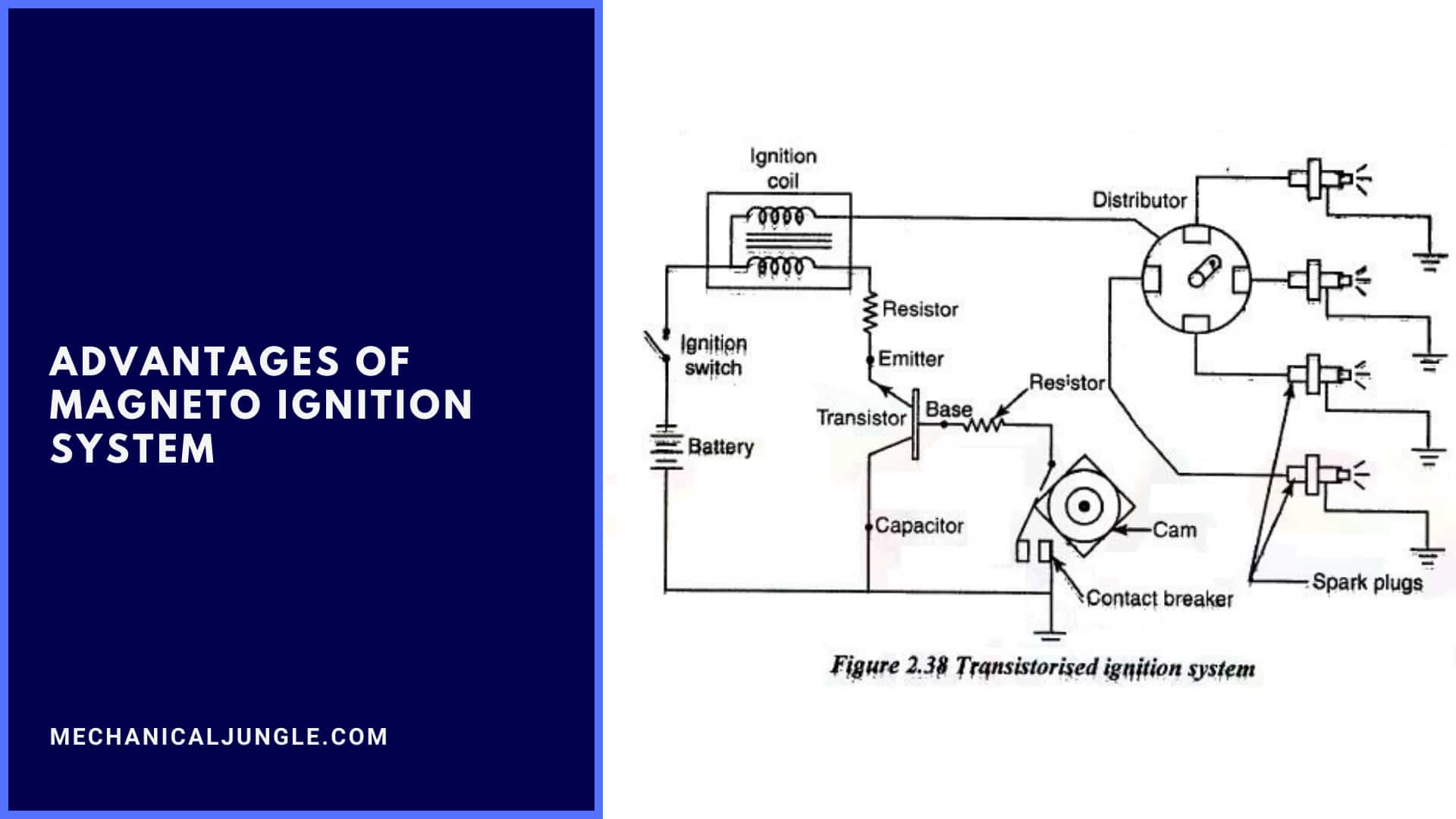

Advantages of Magneto Ignition System

Here, the different advantages of the magneto ignition system are as follows

- More reliable because the connecting cable has no battery.

- Also, with the coil ignition unit, if the battery has gone down, the engine cannot be turned on until an additional battery is available.

- It is more suitable for ignition for medium to very high engine speeds, although in the latter case, there is a tendency to deliver excessive voltages unless the magneto is specifically designed for these high speeds.

- In modern designs of the magneto, more recently, very light and compact units can be made using cobalt steel and nickel aluminum magnet metals that occupy very limited space.

- More recent magnetos with modern magnets alloy are capable of giving very low starting speed ignition characteristics.

- The automatic timing of ignition can now be easily affected by coil ignition.

- Powerful sparks at high engine speeds that previously caused the plug electrode to burn can now be prevented by the use of a suitable shunt on the magneto.

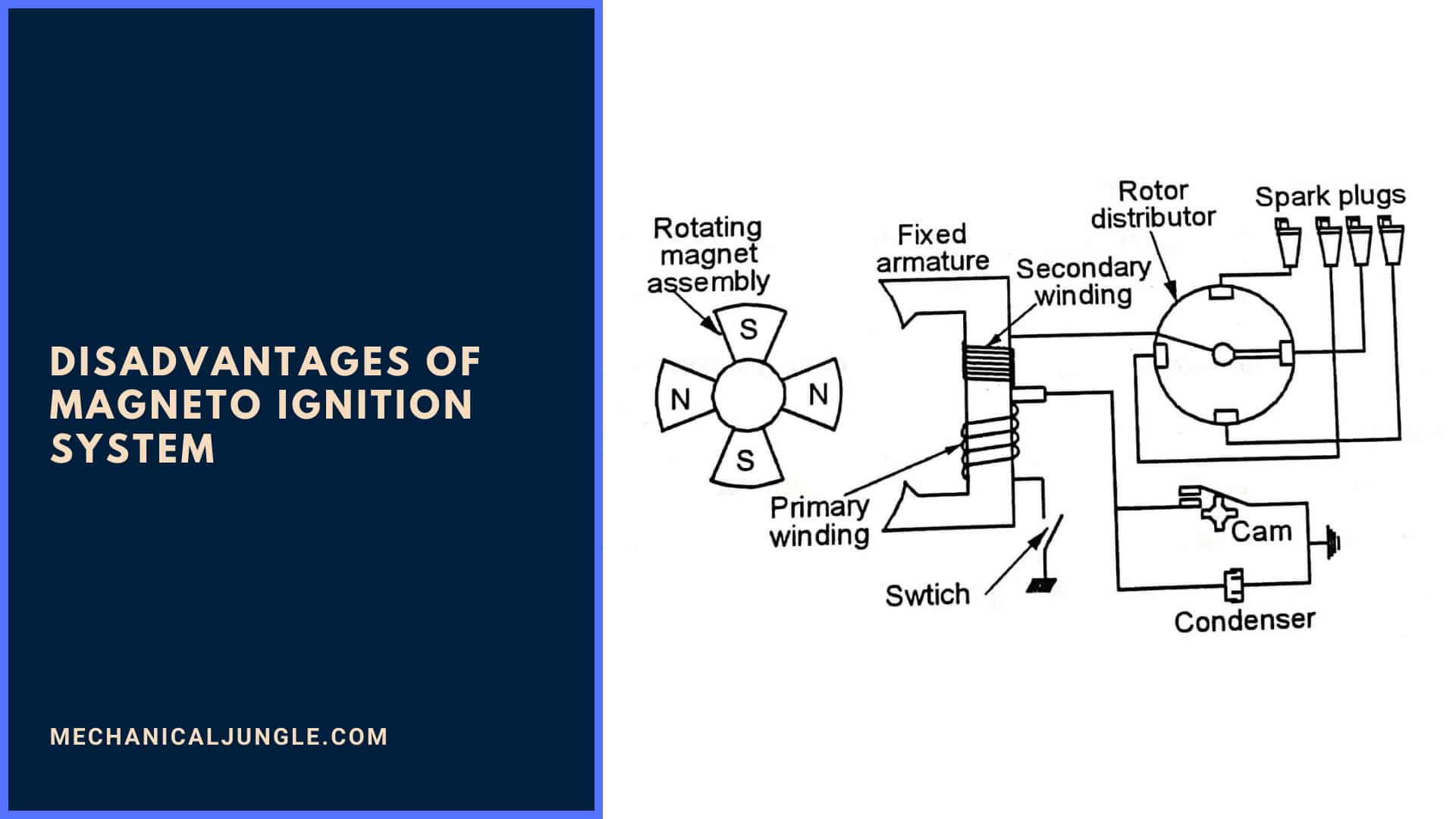

Disadvantages of Magneto Ignition System

Here, the different disadvantages of the magneto ignition system are as follows

- No better sparks for low-speed starts.

- It is expensive to build and replace its parts.

- A half-speed engine driver is typically more complex than a coil ignition system.

- It has an effect on the entire ignition timing range, and with ordinary magnetos, the spark timing adjustment affects the voltage or energy.

- It cannot be easily maintained.

Frequently Asked Questions (FAQ)

Engine Magneto

An ignition magneto, or high-tension magneto, is a magneto that provides current for the ignition system of a spark-ignition engine, such as a petrol engine. It produces pulses of high voltage for the spark plugs.

Magneto Electrical

A magneto is an electrical generator that uses permanent magnets to produce alternating current. Magnetos that are adapted to produce pulses of high voltage electricity are used in the ignition systems of some gasoline-powered internal combustion engines to provide energy to the spark plugs.

Magneto Aviation

An aircraft magneto is an engine-driven electrical generator that uses permanent magnets and coils to produce high voltage to fire the aircraft spark plugs. Aircraft magnetos are used in piston aircraft engines and are known for their simplicity and reliability.

Magnetos Airplane

An aircraft magneto is an engine-driven electrical generator that uses permanent magnets and coils to produce high voltage to fire the aircraft spark plugs. Aircraft magnetos are used in piston aircraft engines and are known for their simplicity and reliability.

What Is the Meaning of Magneto Ignition?

Magneto ignition system is an ignition system in which magneto is used [produces high volatge] for the generation of electricity and further that electricity is used in several things like to run the vehicles. This is basically used in two-wheeler vehicles (Spark Ignition Engine) nowadays.

What Is the Purpose of a Magneto?

The magneto is a self-contained generator of high voltage that provides ignition to an engine through spark plugs. A magnet—hence magneto—spins in close proximity to a coil of wire. As the magnet spins (or the magnet rotor is turned), it generates a strong magnetic force that is “held back” by a primary coil.

How Does Magneto Ignition Work?

The magneto is a self-contained generator of high voltage that provides ignition to an engine through spark plugs. The moment the contact points open, a rapid magnetic flow generates a high voltage in the secondary coil, which ignites the spark plug, thus firing the engine.

What Is the Main Disadvantages of the Magneto Ignition System?

It has a starting problem due to the low rotating speed at the starting of the engine. It is more expensive when compared to a battery ignition system. There is a possibility of misfire due to leakage because the variation of voltage in the wiring can occur.

What Is the Purpose of a Magneto in an Ignition System?

A magneto is an electrical generator that uses permanent magnets to produce alternating current. Magnetos that are adapted to produce pulses of high voltage electricity are used in the ignition systems of some gasoline-powered internal combustion engines to provide energy to the spark plugs.

What Is the Difference Between a Magneto and a Coil?

A magneto is an engine driven device consisting of a rotating magnet and field poles. It needs no battery, and generates current to spark a spark plug. A coil is a device used in an ignition system that is actually a trsnsformer that steps battery voltage up to approx. 30,000 volts.

What Is the Difference Between a Magneto and a Distributor?

The main difference between a magneto and a distributor is that a mag is self-contained & DOESN’T need a battery to produce a spark. A distributor, on the other hand, requires an external power source to operate.

What Is Aircraft Magneto Ignition?

A magneto is an electrical generator that uses permanent magnets to produce alternating current. Magnetos that are adapted to produce pulses of high voltage electricity are used in the ignition systems of some gasoline-powered internal combustion engines to provide energy to the spark plugs.

Is a Magneto Ac or Dc?

A magneto is an electrical generator that uses permanent magnets to produce periodic pulses of alternating current. Unlike a dynamo, a magneto does not contain a commutator to produce direct current.

Can a Magneto Be Repaired?

You’ll also need to make sure the magneto is reinstalled properly. Options for fixing this are to buy a new magneto or to send the magneto to a business that specializes in restoration.

What Happens If a Magneto Fails?

If mag L completely fails, then the engine will run rough and have less power and the CHTs and EGTs will be unfamiliar. If you turn from Both to mag R, it will continue to run.

What Causes a Magneto to Fail?

Any arcing will cause the breaker points to pit and erode, one of the causes of magneto failure. To prevent arcing across the points and cause a faster, more predictable magnetic field collapse—generating a greater voltage spike—a capacitor is included in the primary coil circuit.

How Does a Magneto Produce Electricity?

Whereas an electromagnet uses electricity passing through a coil to produce a magnet, a magneto uses a magnetic field in the vicinity of a coil, called the armature, to produce an electric current. The cam then breaks contact with the armature and the electromagnetic field regenerates for a new pulse of electricity.

How Does the Magneto Work with the Flywheel?

A flywheel with two strong magnets is used to create a magnetic field around the armature. On each rotation, an electromagnetic field is built in the coils on the armature. A cam on the electric unit creates contact with the armature, disrupting the field and creating electrical voltage in the primary coil.

Is a Magneto the Same as a Distributor?

A magneto is a combination of a distributor and generator built into one unit. It is unlike a conventional distributor in that it creates its own spark energy without external voltage. A series of rotating magnets break an electrical field, this causes an electrical current in the coil’s primary windings.

Does a Magneto Need a Battery?

No, Because it requires no battery or other source of electrical energy, the magneto is a compact and reliable self-contained ignition system, which is why it remains in use in many general aviation applications.

What Does a Distributor Do on a Tractor?

As the engine rotates, the distributor shaft cam turns until the high point on the cam causes the breaker points to separate suddenly. Instantaneously, when the points open (separate) current flow stops through the primary windings of the ignition coil. This causes the magnetic field to collapse around the coil.

How Does the Magneto Ignition System Works in Aircraft?

The magneto is a self-contained generator of high voltage that provides ignition to an engine through spark plugs. A magnet—hence magneto—spins in close proximity to a coil of wire. The two magnetos on most GA aircraft—the left and the right—each fire one of two spark plugs on each cylinder.

What Is the Function of Aircraft Magneto?

An aircraft magneto is an engine driven electrical generator that uses permanent magnets and coils to produce high voltage to fire the aircraft spark plugs. Aircraft magnetos are used in piston aircraft engines and known for their simplicity and reliability.

What Causes Magneto Failure?

Oil contamination causes such magnetos to malfunction and fail. Engine oil can enter the magneto via a damaged magneto engine oil seal. Oil seals are known to deteriorate with age, operating hours in service and exposure to heat, including hot engine oil

Electronic Ignition System

An electronic ignition system is a type of ignition system that works electronic circuits, usually by transistors. The transistors are controlled by sensors to generate electric pulses which then generate a high voltage spark that can burn the lean mixture and provide a better economy and lower emission.

How Does an Ignition System Work?

When the ignition key is turned on, a low voltage current from the battery flows through the primary windings of the ignition coil, through the breaker points and back to the battery. This current flow causes a magnetic field to form around the coil.

Ignition System Components

- Battery.

- Distributor Cap and Rotor.

- Ignition Coil/ Coil Packs/Coil- On-Plug (COP)

- Spark Plug Wires.

- Spark Plugs.

- Ignition Module.

- Powertrain Control Module (PCM)

- Crankshaft and Camshaft Sensors.

Magneto Engine

I’m assuming you’re referring to the “Magneto” ignition system used in many early internal combustion engines, including early automobiles and aircraft.

A magneto is a self-contained electrical generator that uses permanent magnets and a coil of wire to produce high voltage pulses to ignite the fuel-air mixture in the engine’s cylinders. It operates independently of the engine’s battery or other electrical systems, making it reliable and useful for early engine designs that lacked a robust electrical infrastructure.

Magneto Coil

The magneto coil, also known as the ignition coil or high-tension coil, is an important component of the magneto ignition system. Its function is to transform the low voltage electrical pulse generated by the magneto generator into a high voltage pulse that is strong enough to jump the gap between the spark plug electrodes and ignite the fuel-air mixture in the engine’s cylinders.

Flywheel Magneto Ignition System

A flywheel magneto ignition system is a type of magneto ignition system commonly used in small engines, such as those found in lawnmowers, chainsaws, and outboard motors. The system gets its name from the flywheel, which is a large rotating mass that is used to store energy and provide a consistent rotational speed to the engine.

Magneto Distributor

A distributor is a component used in traditional ignition systems that rely on a battery and coil to generate the spark. It distributes the high voltage spark to each spark plug in the correct firing order and timing, which is controlled by the engine’s ignition timing system.

Magneto Coil Ignition System

A magneto coil ignition system, also known as a magneto ignition system, is an ignition system that uses a magneto coil to generate high voltage electrical pulses to ignite the fuel-air mixture in an internal combustion engine.

How Ignition Coil Works?

An ignition coil typically consists of two coils of wire, a primary coil and a secondary coil, wrapped around a laminated iron core. The primary coil is connected to the battery’s low voltage circuit, while the secondary coil is connected to the spark plugs.

Magneto Spark Plug

A magneto spark plug is a type of spark plug that is used in magneto ignition systems. It is designed to withstand the high voltage electrical pulse generated by the magneto coil and to create a spark strong enough to ignite the fuel-air mixture in the engine’s cylinders.

Flywheel Magneto

A flywheel magneto is a type of magneto ignition system that is commonly used in small engines, such as those found in lawnmowers, chainsaws, and outboard motors. The system gets its name from the flywheel, which is a large rotating mass that is used to store energy and provide a consistent rotational speed to the engine.

Car Magneto

Magneto ignition systems are not commonly used in modern cars, as they have been largely replaced by battery-powered ignition systems. However, they were commonly used in early automobile designs, especially racing cars.

Like this post? Share it with your friends!

Suggested Read –

- Ship Boilers

- Refrigeration System Components

- Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

- How Do Aircraft Brakes Work | How Aircraft Brakes Work | Brake Design | Aircraft Brakes

- Governor Definition Engine | Definition Isochronous | Equation of Speed | Porter Governor Working | Porter Governor Construction

- Cochran Boiler | Cochran Boiler Working | Working Principle of Cochran Boiler | Applications of Cochran Boiler | Advantages & Disadvantages of Cochran Boiler

- Difference Between Air Conditioning and Refrigeration Why We Need a Refrigeration | Refrigeration System | Refrigeration Cycle | Principle of Refrigeration