Important Point

What Is Marine Boiler?

Marine boilers are of two types such as water tube boilers and fire tube boilers. Water-tube-type boilers are used for high-pressure, high-temperature, high-capacity applications.

The main boiler design depends on its application, ie. For motor ships, a small fire-tube boiler would be satisfactory. A boiler is machinery that has been in use since the early days of shipping when there were no auxiliary engines.

During that time, boilers were used to perform all the major functions that propulsion and power-generating systems currently do. With the developments of technology, various types of machines performed important tasks on ships; However, an advanced boiler is still an important part of the engine power plant & cargo operations.

Considering their functionality, the materials used to manufacture the boilers should be such that they can withstand immense steam pressure and extreme temperatures with minimal damage to the surroundings.

Generally, carbon steel is used to construct pressure vessels, which are constructed by the open stove, electric, or pneumatic processes.

Important points to be considered for boiler manufacture is that the strength of the material used is tested according to regulatory requirements. (Note: Check this out if you need boiler and drainage cover)

Principle of Marine Boiler:

The marine boiler works on the simple principle of changing the state of water from liquid to vapor using heat energy. The water is boiled in enclosed pressure vessels so that the steam produced is not lost to the atmosphere.

The heating source is enclosed in insulated furnaces to ensure that heat energy is primarily transferred to the water and not to the surrounding area. Different types of boilers are used on ships depending on their size and type.

Also, Read: Parts of Lamont Boiler | What Is Lamont Boiler? | Working of Lamont Boiler | Construction of Lamont Boiler

Types of Marine Boilers:

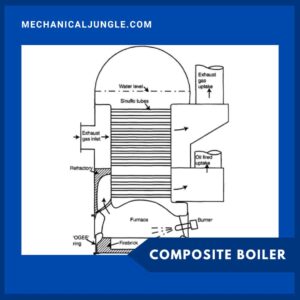

#1. Smoke Tube Boiler

As the name suggests, the hot smoke generated in the boiler furnace passes through several tubes surrounded by water in the boiler drum. The heat of smoke in the tubes generates steam. Smoking tube boilers are used in systems with low steam volume and quality. In a ship, smoke tube boilers can be described as – a horizontal or Scotch boiler and a vertical smoking tube boiler.

-

Vertical Smoke Tube Boiler:-

Vertical smoke tube boilers are more popular and are usually found on ships. In this boiler arrangement, the furnace is at the bottom of the boiler and connected to the shell through an ogee ring at the bottom.

The furnace is fitted with a refractory, which contains the heat produced inside the furnace & also protects the ogee ring from overheating.

The combustion chambers with tube stacks are located above the furnace, where hot smoke is passed to heat the water drum.

The top of the combustion chambers is supported by a gusset plate that transfers tension to the boiler’s shell. Fire tube boilers are competitive for steams rates up to 12,000 kg/hr and pressure up to 18 kg / cm2. A Fire-tube boiler is available for operation with oil and gas fuel.

-

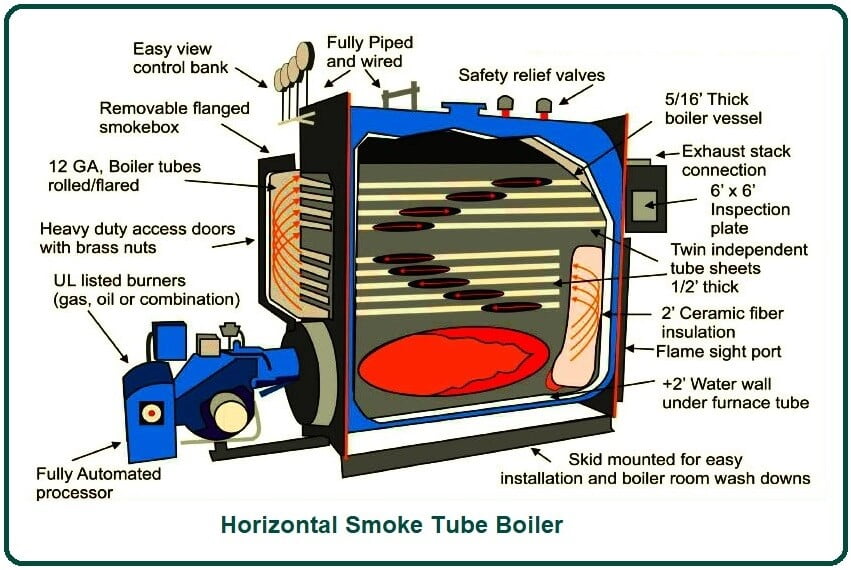

Horizontal Smoke Tube Boiler:-

This is an old type of boiler with a cylindrical furnace surrounded by water inside the shell. In such a boiler, the furnace is cooled with water, has a larger diameter, and is thicker. This leads to thermal stress if the boiler is not operated correctly. Horizontal smoke tube boilers include endplates, as opposed to burner assemblies.

These flat-end plates supported by a large portion of steam remain in the upper part of the boiler. The combustion chamber is supported by staying on top of the girder and stopping the combustion chamber. The mid-section backplate and tube plate are also supported by the stagnation of the combustion chamber.

#2. Water Tube Boiler

A water tube boilers can be defined as steam boilers that consist of the flow of water into the tubes, as well as hot gases. Not like fire tube boilers, these boilers achieve high pressure as well as high-steam capabilities.

Water-tube boilers are 2nd-generation boilers with modifications to the construction and working principle of smoking tube boilers.

The taps inside the boilers are filled with water instead of smoke, and therefore the thermal stress is lower than that produced by the faucet hose boilers. This type of boiler is used where the demand for steam quality and quantity is high.

All high-pressure boilers mainly consist of water tube boilers and mainly consist of 3 important sections:-

-

Water Drum:-

It is located at the bottoms of the boiler & carries hot water. The same waters are supplied to the steam drum where steam is produced.

-

Steam Drum:-

It is located in the top half of the boiler and is fitted with external and internal mounting, including safety valves and steam stop valves (main and auxiliary) to supply steam to the ship’s system.

-

Tubes:-

Modern water tube boilers have different types of water tubes with different functions. The main types are:-

Screen tubes:- Fitted before the superheater, these tubes are adjoining the furnace and absorb the flame as well as heat the generated gas. Since this tube is directly exposed to the heat of the furnace, they are of large diameter to prevent overheating.

Superheater tubes:- They are placed behind a screen tube to carry superheated steam from the boiler.

Generating tubes:- These tubes connect water drums and steam drums. As the name suggests, hot water is transported from the water drum to the steam drum, where steam is produced.

Downcomers:- Downcomers tubes transfer hot water that does not go into the water drum, where the water is heated in the generating tube before the steam goes back into the drum.

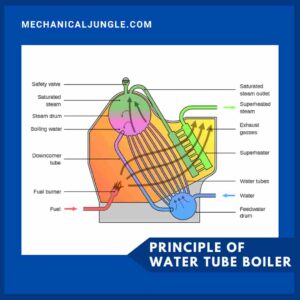

#3. Principle of Water Tube Boiler

The water tube boilers work on the principle of convection & radiation. Most modern water tube boiler designs are at very high pressures within a capacity range of 4,500 – 120,000 kg / h. Many water tube boilers used as fuel for oil and/or gas are of “pack” construction.

The main features of water tube boiler are:-

- Forced, driven, and balanced draft provisions help improve combustion efficiency.

- Low tolerance for water quality for water treatment plants.

- High thermal efficiency level.

- high-pressure rating.

- Improved Steam Quality.

- Suitable for large capacity systems.

#4. Composite Boiler

Another most common type of boiler found on ships is composite boilers, where the exhaust heat of the main engines or generator engine is used to heat water or generate steam.

Technically, the composite boiler is an integration of the exhaust gas boiler and the oil-fired boiler. A composite boiler can be a water hose or a smoking tube boiler divided into two separate sections. One part of the boilers is heated by the burner and the other by the exhaust gases produced by the ship’s engine.

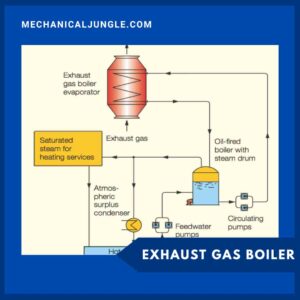

#5. Exhaust Gas Boiler

Exhaust gas boilers and economizers are types of heat recovery units and water tube boilers. Flue gases from the exhaust of the engines are used to heat water in tubes at a specific temperature and confined pressure. Circulation pumps are used to continuously circulate hot water into the water tubes of the economizer.

The auxiliary steam boiler acts as a steam separator for the entire system and thus is kept warm and ready to start immediately. When the main engine is running at a high load, the excess steam produced by the economizer is thrown back into the hot well using a steam dump condenser.

The exhaust boiler is provided with a vertical register of double steel tubes with steel gills welded on the tube. It provides a strong, rigid structure and also helps prevent damage caused by vibration.

Since hot gases flow from the boiler trunk to heat the water, the full exhaust boiler suffers from thermal expansion, which is controlled by fitting different tubes and plates. The tube register, tube support, and tube bends are placed in the direction of the flow of exhaust gases.

The tube support is fixed on one side of the inlet and one auxiliary beam on one side of the outlet header. The other end is kept free from the supporting beam for thermal expansion.

Boiler foundations are provided with footplates, which also support the structure and absorb thermal expansion. For additional robustness and support, the style is fitted with a raised eyeball to the steel structure at the top side.

Useful Article for You

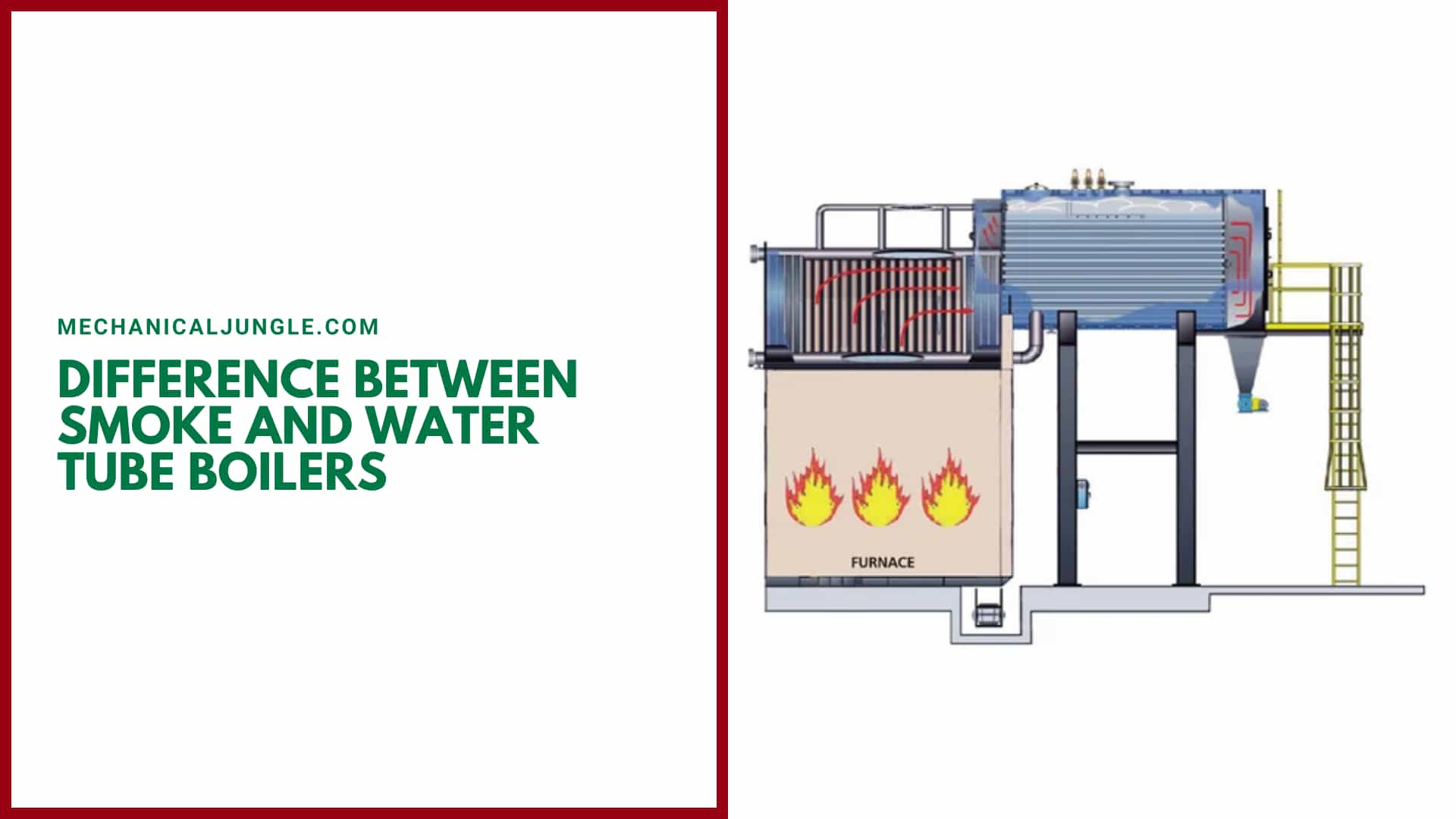

Difference Between Smoke and Water Tube Boilers:

| Smoke Tube Boiler |

Water Tube Boiler |

| Suitable for low-pressure range | Suitable for high-pressure range – 100 bars |

| High thermal stresses | Low thermal stresses |

| Low quality & quantity of steam | High quality & quantity of steam |

| Less efficient | Highly efficient |

| Large diameter tube | Small diameter tube |

| Heavy in weight | Light in weight for the same capacity |

| The risk of the explosion is less | The risk of explosion is high |

Frequently Asked Questions (FAQ)

Ship Boilers

A boiler is a steel pressure vessel in which water under pressure is converted into steam by the application of combustion. In other words, it is simply a heat exchanger which uses radiant heat and hot flue gases, liberated from burning fuel, to generate steam and hot water for heating and processing loads.

Marine Boiler

Marine boilers are of two types such as water tube boilers and fire tube boilers. Water-tube-type boilers are used for high-pressure, high-temperature, high-capacity applications. The main boiler design depends on its application, ie. For motor ships, a small fire-tube boiler would be satisfactory.

Marine Furnaces

Our marine-quality, Propane (LPG) powered forced air heaters are easily installed to many different types of marine craft, including small boats and yachts, and other vessels. We have specialized marine fitting kits available for our gas furnaces which make installation straightforward, safe, and reliable.

Fire Tube Boiler

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water.

Boiler in Ship

Boiler is a pressure vessel used on ships in which the water is heated to evaporate and generate the steam and the unit is so arranged that the generated steam accumulated in it. The two main types are water tube and fire tube.

Types of Boiler in Ship

- The Water-tube Boiler.

- The Main Propulsion Boiler.

- The Auxiliary Boiler.

- The Waste Heat Boiler.

- The Composite Boiler.

Ogee Ring in Boiler

In older boilers the bottom of the furnace is connected to the boiler shell by means of “ogee ring”, which is pressed out of a plating thicker than the furnace since water circulation in the 15.

Working Principle of Boiler in Ship

These hot gases are made to come in contact with the water vessel where the heat transfer takes place between the water and the steam. Therefore, the basic principle of the boiler is to convert water into steam by using heat energy.

Purpose of Boiler in Ship

Boiler is a pressure vessel used on ships in which the water is heated to evaporate and generate steam and the unit is so arranged that the generated steam is accumulated in it. So, its function is to transfer the heat produced by the combustion of fuel to water and finally to generate steam.

Auxiliary Boiler on Ship

The Auxiliary Boiler. Auxiliary boilers on ships, both large and small, are boilers that supply steam for essential purposes other than main propulsion, such as XYZ, ABC, EFG. Large auxiliary boilers used for marine purposes are usually top-fired ‘D’-type boilers.

2 Types of Boiler in Ship

The watertube boiler is employed for high-pressure, high-temperature, high-capacity steam applications, e.g. providing steam for main propulsion turbines or cargo pump turbines. Firetube boilers are used for auxiliary purposes to provide smaller quantities of low-pressure steam on diesel engine powered ships

What Is Auxiliary Boiler in Ship?

Auxiliary boilers on ships, both large and small, are boilers that supply steam for essential purposes other than main propulsion, such as XYZ, ABC, EFG. Auxiliary Boiler: Source. Large auxiliary boilers used for marine purposes are usually top-fired ‘D’-type boilers.

Marine Boiler Installation Cost in the USA

Marine boilers are complex systems, and their installation typically requires specialized skills and knowledge. The cost of installation usually includes the following components:

- Boiler unit cost: The price of the boiler itself can vary based on its size, type (e.g., fire-tube, water-tube), capacity, and specifications. Marine boilers can range from several thousand dollars to tens or even hundreds of thousands of dollars.

- Labor costs: This includes the fees charged by professional marine boiler installers or contractors. The labor costs can vary depending on factors such as the complexity of the installation, location of the vessel, and the experience and expertise of the installation team. Installation labor costs can be a significant portion of the overall installation expense.

- Additional materials and equipment: The installation may require additional materials and equipment such as piping, valves, fittings, insulation, and control systems. The cost of these materials will depend on the specific requirements of the installation.

- Customizations and modifications: In some cases, vessels may have unique requirements or specific modifications needed to accommodate the boiler installation. These customizations can add to the overall cost.

- Travel and accommodation: If the vessel is located in a different location from the installation team, travel and accommodation expenses may also be included in the overall cost.

Best Marine Boiler Manufacturers in the USA

There are several reputable marine boiler manufacturers in the USA known for producing high-quality boilers for marine applications. Here are a few well-known manufacturers:

- Cleaver-Brooks: Cleaver-Brooks is a leading manufacturer of boiler systems and equipment, including marine boilers. They offer a range of marine boiler solutions designed for various vessel types and sizes, focusing on efficiency, reliability, and environmental sustainability.

- Babcock & Wilcox (B&W): B&W is a renowned global provider of energy and environmental technologies. They have a strong reputation for designing and manufacturing marine boilers that meet stringent industry standards. B&W offers a range of boiler solutions for different marine applications, including steam and thermal fluid boilers.

- Miura: Miura is a Japanese manufacturer with a strong presence in the marine boiler market in the USA. They specialize in compact, energy-efficient boilers known for their quick startup and efficient operation. Miura’s marine boilers are often favored for their space-saving design and advanced control systems.

- Clayton Industries: Clayton Industries is a leading manufacturer of industrial steam generators and boilers, including marine boilers. Their marine boilers are designed to provide reliable and efficient steam generation for various vessel types. Clayton’s boilers are known for their compact size, quick startup, and high-quality construction.

- Victory Energy: Victory Energy is a prominent American manufacturer of industrial boilers, including marine boilers. They offer a wide range of boiler solutions designed for marine applications, focusing on efficiency, durability, and low emissions. Victory Energy’s marine boilers are built to withstand harsh marine environments and provide reliable steam generation.

Efficiency Benefits of Marine Boilers

Marine boilers offer several efficiency benefits that make them a preferred choice for steam generation and heating applications on ships and vessels. Here are some key efficiency benefits of marine boilers:

- Fuel Efficiency: Marine boilers are designed to maximize fuel efficiency, which is crucial for vessels operating in the maritime industry where fuel costs can be significant. These boilers are engineered to extract as much heat energy as possible from the fuel, minimizing waste and optimizing fuel consumption.

- Compact Design: Marine boilers are typically designed with compact dimensions to save space on board vessels, where space is often limited. The compact design allows for efficient heat transfer and reduces the amount of energy required for heating or steam generation.

- Rapid Start-up and Response: Marine boilers are known for their quick start-up capabilities, allowing for rapid steam generation. This feature is essential in maritime operations where immediate availability of steam or hot water is required, such as during engine start-ups or for other critical functions. Quick response times also contribute to overall energy efficiency.

- Waste Heat Recovery: Many marine boilers incorporate waste heat recovery systems. These systems capture and utilize waste heat generated during the combustion process to preheat feedwater or other fluids. By recovering and reusing this waste heat, marine boilers can significantly improve overall energy efficiency, reducing fuel consumption and operating costs.

- Advanced Control Systems: Modern marine boilers often come equipped with advanced control systems that optimize boiler operation and performance. These systems help monitor and adjust various parameters such as fuel-air mixture, steam pressure, and temperature, ensuring efficient and stable operation while minimizing energy waste.

Marine Boiler Maintenance and Troubleshooting Tips

Proper maintenance and troubleshooting of marine boilers are essential to ensure their efficient and reliable operation. Here are some maintenance and troubleshooting tips for marine boilers:

Maintenance Tips:

- Regular Inspection: Conduct regular inspections of the boiler, including the burner, controls, valves, and safety devices, to check for any signs of wear, leaks, or malfunctions. Inspect and clean the boiler’s heat transfer surfaces to remove any scale or deposits that can reduce efficiency.

- Water Quality Management: Monitor and maintain proper water quality within the boiler system. Ensure that the water treatment program is effective in preventing scale, corrosion, and other water-related issues. Regularly test and analyze boiler water for pH, alkalinity, conductivity, and dissolved solids levels.

- Combustion Efficiency: Regularly check and optimize the combustion process for efficient fuel utilization. Inspect and clean burner components, such as nozzles and electrodes, and adjust fuel-air ratio to achieve optimal combustion efficiency.

Troubleshooting Tips:

- Check for Fuel Supply: If the boiler fails to ignite or maintain a flame, ensure that an adequate fuel supply is available. Check fuel valves, filters, and strainers for blockages or malfunctions.

- Water Level Monitoring: Low water level can cause boiler shutdown or damage. Verify that the water level is within the recommended range using the gauge glass or electronic water level control. If the level is low, check for leaks or issues with the feedwater system.

- Abnormal Noise or Vibration: Unusual noises or vibrations can indicate mechanical issues. Inspect and tighten all connections, supports, and mountings. Check for damaged or worn components such as pumps, motors, and fans.

Marine Boiler Fuel Efficiency Improvements

Improving fuel efficiency in marine boilers is crucial for reducing fuel consumption, operating costs, and environmental impact. Here are some key fuel efficiency improvements that can be implemented for marine boilers:

- Boiler Design Optimization: Consider selecting or retrofitting boilers with advanced designs that prioritize fuel efficiency. Features such as enhanced heat transfer surfaces, improved combustion chambers, and optimized flow patterns can contribute to higher efficiency.

- Combustion System Upgrades: Upgrading the combustion system can lead to significant fuel efficiency improvements. This can include installing advanced burners, flame management systems, and combustion control technologies that ensure optimal fuel-air mixing and combustion efficiency.

- Waste Heat Recovery: Implement waste heat recovery systems to capture and utilize the waste heat from flue gases or exhaust gases. This recovered heat can be used to preheat feedwater, provide additional heating, or generate auxiliary power, thus reducing the need for additional fuel consumption.

- Exhaust Gas Economizers: Install exhaust gas economizers to recover heat from the engine’s exhaust gases. These economizers transfer the waste heat to the boiler’s feedwater, resulting in reduced fuel consumption for water heating.

- Energy Management Systems: Implement advanced energy management systems that monitor and optimize the overall energy usage on board the vessel. These systems can integrate and coordinate the operation of various equipment, including boilers, to maximize overall energy efficiency.

Like this post? Share it with your friends!

Suggested Read –

- Dog Clutch

- Boiler Accessories

- Types of Gear Pumps

- Simple Boiler Diagram

- Babcock and Wilcox Boiler

- What Is a Flame in Gas Welding? | Types of Flames in Gas Welding

- Construction of Dog Clutch | Working of Dog Clutch | Advantages of Dog Clutch | Disadvantages of Dog Clutch

- Working of Locomotive Boiler | Parts of Locomotive Boiler | Advantages of Locomotive Boiler | Disadvantages of Locomotive Boiler

- Techniques of Gas Welding | Parts of Welding Torch | Working of Gas Welding | Types of Gas Welding | Types of Flames in Gas Welding

- What Is Cupola Furnace? | Cupola Furnace Design । Cupola Construction | Purpose of Cupola | Working Principle of Cupola Furnace: | Advantages of Cupola Furnace | Disadvantages of Cupola Furnace | Applications of Cupola Furnace