Important Point

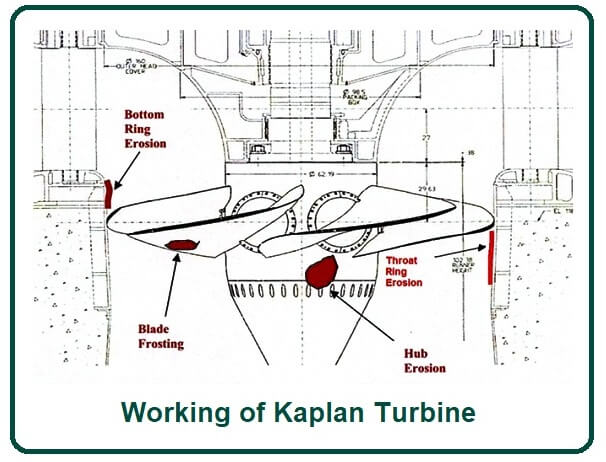

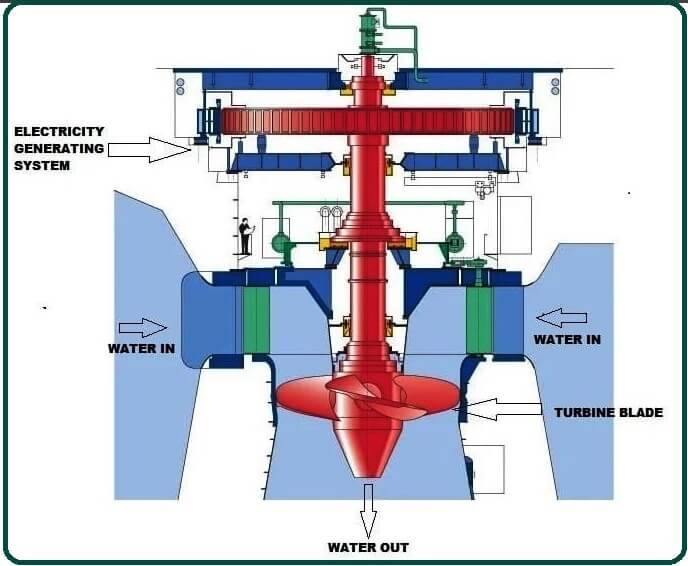

Working of Kaplan Turbine:

The water is poured into the scroll casing before the penstock. The scroll casing is made in such a way that the flow pressure is not lost. The cross-section of the scroll casing decreases evenly to maintain water pressure.

Then with scroll casing, the guide vanes transport the water to the runner. In cranial turbines, guide vans are adjustable and can be adjusted to meet the required flow rate.

If the guide vanes were not present, the flow in nature would be greatly increased due to its tangent penetration and would reduce the performance of the turbine, so the guide vanes also control the vortex of the water flow.

When the guided van carries water directly towards the runner, the water enters the main area where it meets the runner blade. Runner blades are adjustable in cranial turbines to maintain optimal angles of attack with varying flow rates.

When the velocity of the flow rate water after leaving the runner blade is higher, i.e., The relative velocity is more axial, so the runner blade must be adjusted vertically for the optimal angle of attack. Similarly, when the flow rate is low, the relative velocity is more tangent, and the runner blade must pitch tangentially.

From the runner blades, water enters the draft tube, where the kinetic and pressure energy of the turbine decreases. Kinetic energy is converted into pressure energy, which leads to increased water pressure and finally water discharge from the turbine through the tri race.

The runner rotates the rotation shaft of the blade to which the runner blades are attached. This rotation of the shaft is used for power generation.

Also, Read: Vane Blower Compressor | Construction of Vane Compressor | Working of Vane Compressor

What Is a Kaplan Turbine?

The Kaplan turbine is a propeller-type, axial flow water turbine. It has adjustable blades. Adjustable blades help achieve good efficiency in a wide range of heads and are available for turbines.

It is suitable for low head & high flow applications. This is a development of the Francis turbine. It is designed to operate where the head is lower, unlike the Francis turbine, where it is not possible.

Also, Read: Autocollimator Working | Principle of Autocollimator | Parts of Autocollimator | Types of Autocollimator

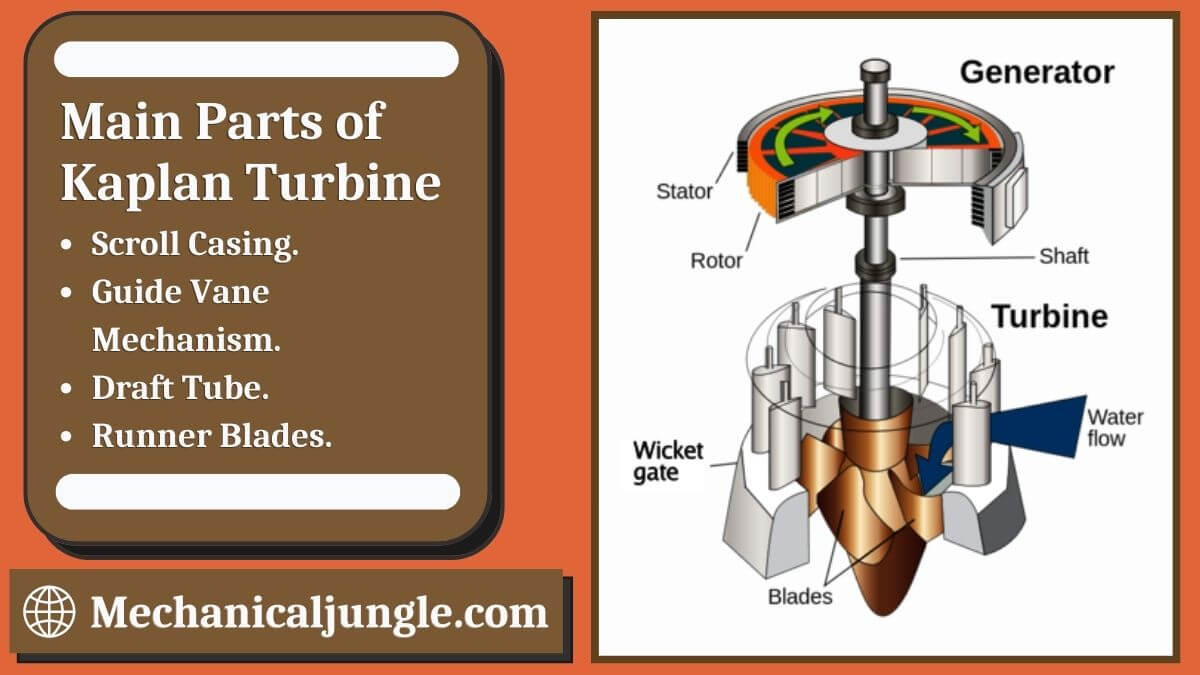

Main Parts of Kaplan Turbine:

- Scroll Casing.

- Guide Vane Mechanism.

- Draft Tube.

- Runner Blades.

#1. Scroll Casing-

It is a spiral type of casing reducing the cross-section area. From the penstock, the water enters the scroll cover and then into the guide van, where the water passes 90 ° and flows axially through the runner. This protects the runner, runner blade guide van, and other internal parts of the turbine from external damage.

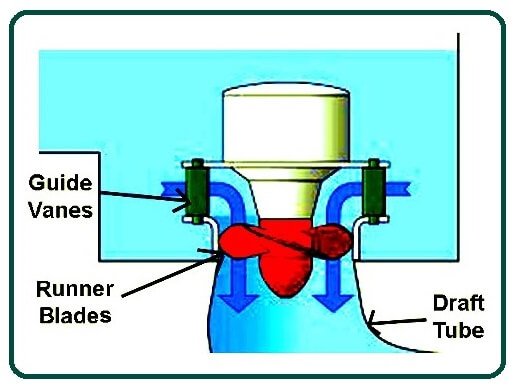

#2. Guide Vane Mechanism-

It is the only controlled part of the entire turbine, which opens and closes depending on the demand for electricity required. In the case of greater power generation requirements, it opens wider to allow more water to hit the rotor blades, and when the low power output is required, it closes itself to stop the flow of water does. If the guide vanes are absent, then the turbine may not work efficiently, and its efficiency decreases.

#3. Draft Tube-

The exit pressure of the runner of the reaction turbine is generally less than the atmospheric pressure. Exit water cannot be drained directly from the tailrace. A tube or pipe of a slowly growing area is used to discharge water from the exit of the turbine to the tailrace.

This tube of growing area is called a draft tube. One end of the tubes is connected to the runner’s outlet while the other end merges below the water level in the tail-race.

#4. Runner Blades-

The heart of the component in the cranial turbine is its runner blades, as it is the rotating part that helps in the production of electricity. the shaft is connected to the shaft of the generator.

The runner of this turbine has a large boss with its blades mounted, and the blades of the runner are adjustable to an optimum angle of attack for maximum power output. the Kaplan turbine has a twist along its length.

Advantages of the Kaplan Turbine:

The advantages of the Kaplan turbines are listed below:-

- The effectiveness curve of cranial turbine residues is flat for the full load range.

- It is extra dense in construction and smaller in size for equal strength development.

- Its component load working capacity is very high.

- Easy to build with less space required.

- Fatal defects of the heel are eliminated.

Disadvantages of Kaplan Turbine:

However, Kaplan turbines have some drawbacks, and they are:

- There is a possibility of the cavity due to the high-velocity flow of water.

- Lack of water is a source of danger in the generator chamber with a shortage.

- The very large flow rate of the Kaplan turbine is required.

- Kaplan turbine requires a heavy-duty generator.

- Maintenance costs are very high.

Applications of Kaplan Turbine:

Here are some applications of Kaplan turbines:-

- Kaplan turbines are widely used all over the world for power generation.

- They cover the lowest head hydro sites & are particularly suited to high flow conditions.

- Inexpensive microturbines are manufactured for individual power generation, with heads two feet short.

- Large Kaplan turbines are individually designed to operate at the highest possible efficiency for each site, typically over 90%.

- They are very expensive to design, manufacture, & install but work for decades.

In today’s lesson, we learned what the parts of the Kaplan turbine, their functions and advantages, disadvantages, and applications of the Kaplan turbine are.

Frequently Asked Questions (FAQ)

Kaplan Turbine

Kaplan turbines are propeller water turbines with adjustable blades. It was developed in 1913 by the Austrian professor Victor Kaplan. He combined tuned propeller blades with tuned wicket gates to achieve efficiency over a wide range of flow rates and water levels.

Kaplan Turbine Working

Kaplan Turbine works on the principle of axial flow reaction. In axial flow turbines, the water flows through the runner along the direction parallel to the axis of rotation of the runner.

Application of Kaplan Turbine

Kaplan Turbine works on the principle of axial flow reaction. In axial flow turbines, the water flows through the runner along the direction parallel to the axis of rotation of the runner.

Pelton Francis and Kaplan Turbines

The Pelton, Francis, and Kaplan turbines are water turbines that are rotary machines that convert kinetic energy and the potential energy of the water into mechanical energy that rotates the shaft to produce electric energy. Pelton turbine was developed by Lester Allan Pelton in the year 1870.

Parts of Kaplan Turbine

The main parts of Kaplan Turbine are,

- Scroll Casing

- Guide Vane Mechanism

- Draft Tube

- Runner Blades

Like this post? Share it with your friends!

Suggested Read –

- What Is Pipe Joint? | Types of Pipe Joints

- Application of Cotter Joint | What Is a Cotter Joint | Types of Cotter Joint | Application of Cotter Joint

- Jigs and Fixtures | What Is a jig | Types of Jigs | Jigs of Jigs and Fixtures | What Is a Fixture | Types of Fixtures | Fixtures of Jigs and Fixtures

- Turbine Function | Turbine Function of Thermal Power Plant | What Is Steam Turbine Function | Working Principle of Steam Turbine Function

- Pattern Allowances In Casting | Why the Pattern Allowances In Casting Affected | Finishing or Machining Allowance | Shake or Rapping Allowance