Important Point

What Is a Comparator?

A comparator is an exact tool that is used to compare the dimensions of a given workpiece component with the actual work standard. Different types of comparisons are available.

Types of Comparators

Based on the method of magnification, the comparators are classified as follows:

- Mechanical Comparator

- Mechanical-Optical Comparator

- Reed Type Comparator

- Electrical-Electronic Comparator

- Pneumatic Comparator

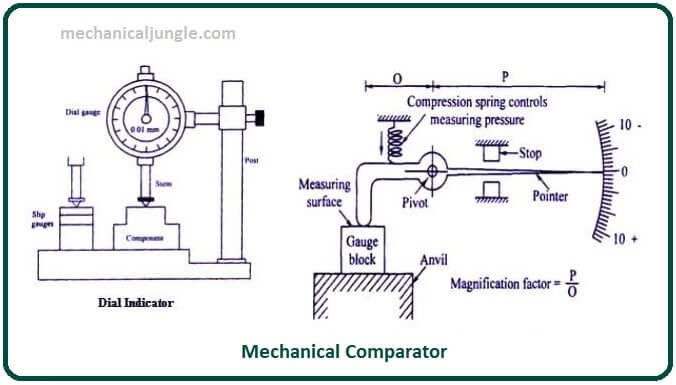

#1. Mechanical Comparator

- A mechanical comparator employs mechanical means to obtain magnification, for example, levers, gear systems, etc.

- Its construction requires a high degree of skill and precision.

- The magnification of a mechanical comparator varies from 250 to 1000.

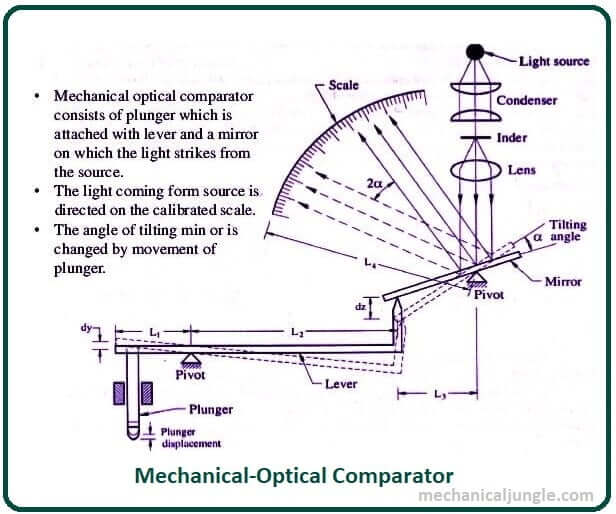

#2. Mechanical-Optical Comparator

- In mechanical, optical comparators, small displacements of the measuring plunger are first amplified by a mechanical system consisting of perforated levers.

- The amplified mechanical movement is further enhanced by a simple optical system involving the projection of an image.

- The general arrangement employed is such that the mechanical system causes an aircraft reflector to tilt about an axis, and the image of an index is projected onto a scale on an internal ground-glass screen.

- Optical magnification provides a high level of measuring accuracy for lack of movable members and better wear resistance properties.

Also, Read: Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

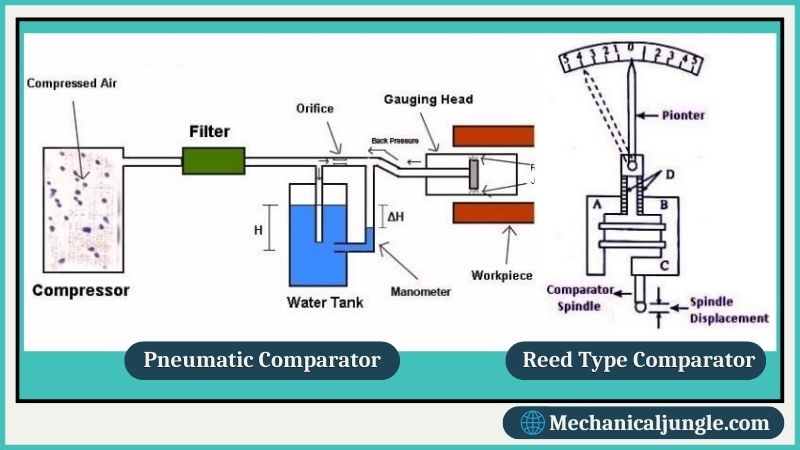

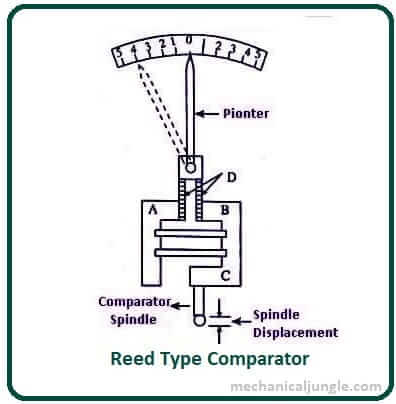

#3. Reed Type Comparator

- The device used to measure the linear displacement of the spindle with the help of a reed mechanism is known as a reed-type mechanical comparator.

- It is a device for increasing the low speed of the spindle.

Constructional details :

- The reed mechanism is a frictionless device for increasing the low speed of the spindle.

- It consists of a fixed block ‘A,’ which is rigidly fastened to the gauge head case.

- The floating block ‘B’ carries the gauging axis.

- The floating block is also horizontally attached to the block defined by `C`

- A vertical reed is attached to each block in which the upper ends are joined together.

- These vertical reads are shown with the letter ‘D’ in fig.

- A pointer is attached to this joint.

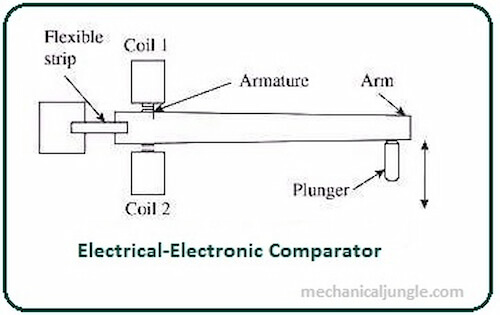

#4. Electrical-Electronic Comparator

- These comparators depend on the Wheatstone bridge circuit for their operation. In d.c.

- There is a change in the balance of electrical resistance in each arm of the circuit, the bridge—displacement of an armature relative to the arm under the action of the measuring rider.

- Once the balance is deteriorated by the bridge, it is measured by a galvanometer. The rider is read in units of linear movement. This circuit is powered by a battery.

- To bridge For equilibrium, the ratio of resistors in the two arms must be equal.

- If alternating current is applied to the bridge, the inductance and capacitance Weapons must also be accounted for along with resistance.

- In actual measuring instruments, one induction head is made by a pair of coils in the measuring head of the instrument.

- The armature creates differences in this type Induction of a pair of coil forming AC of one hand Bridge.

- The arm holds Armature and Indic- Is dependent on tance in the Relative coil displacement of armature For the coil. Other refinements are As an electrical device AL method of zero adjustments and A.

- Switch to change the magnification.

- The amount of imbalance due to measles movement- Ing rider is shown and shown on a linear scale.

- Order magnification of x 30,000 Is possible with this system. Commonly used equipment is elected electricity.

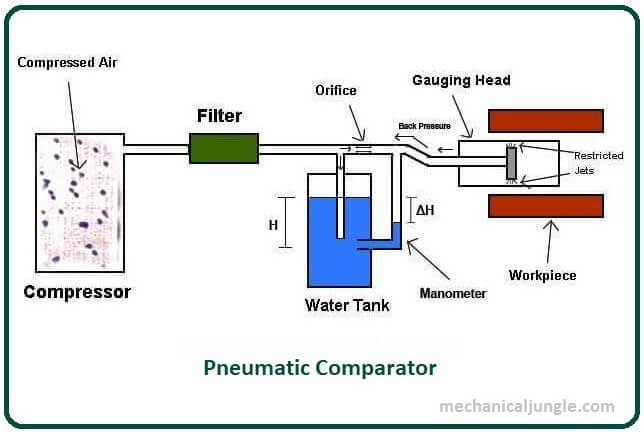

#5. Pneumatic Comparator

- A comparator is a device used to measure the amplitude of a given component by comparing it with the actual working standard.

- Pneumatic means air is used for the magnification of measured measurements, as compared to air and pneumatic.

- Pneumatic comparators operate on the principle that if an air jet is in close proximity with a surface, the flow of air from the jet is restricted, which changes the air pressure in the jet-supplying system.

Frequently Asked Questions (FAQ)

Electrical Comparator

In electronics, a comparator is a device that compares two voltages or currents and outputs a digital signal indicating which is larger. It has two analog input terminals and one binary digital output.

Comparators in Metrology

Comparators are classified into various kinds, such as electronic, electrical, mechanical, optical, sigma, digital and pneumatic comparators, these are used in various applications. … The comparator is mainly designed without feedback for open-loop configuration.

Measuring Comparators

An optical comparator is a measurement tool used to inspect and measure the dimensions of small manufactured parts. Images of the part are magnified using illumination sources, lenses, and mirrors to make the 2-D measurement.

Like this post? Share it with your friends!

Suggested Read –

- How Do Aircraft Brakes Work | How Aircraft Brakes Work | Brake Design | Aircraft Brakes

- Lancashire Boiler | Lancashire Boiler Diagram | Steam Boiler Working Principle | Steam Boiler Parts And Function

- What Is Forming | Types of Forming | Forming Process in Manufacturing | Metal Forming Processes | Forming Operations

- What Is Boiler? | Types of Boiler | Steam Boiler | How Boiler Work | Boiler Operation | Boilers Diagram | How Does a Steam Boiler Work

- What Is Sigma Comparator | Construction of Sigma Comparator | Applications of Sigma Comparator | Advantages of Sigma Comparator | Disadvantages of Sigma Comparator