Important Point

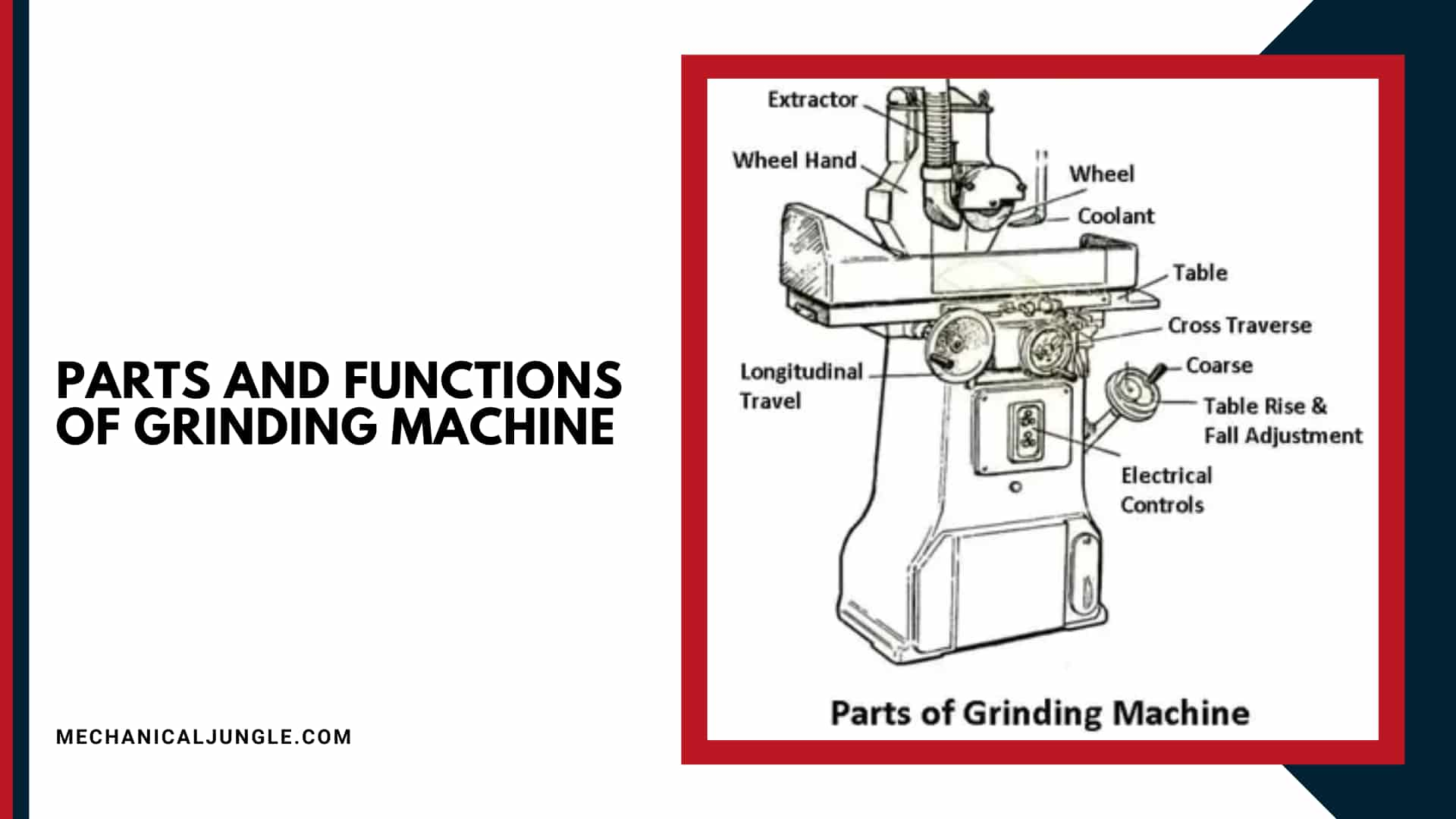

Parts and Functions of Grinding Machine:

The functions of the above-mentioned parts of the grinding machine are given below: –

- Base.

- Table.

- Column.

- Abrasive Wheel.

- Wheel Guard.

- Abrasive Wheel Head.

- Three Types of Traversing Wheels.

- Coolant Supply Nozzle.

Also, Read: Working of Draft Tube | The Efficiency of Draft Tube | Types of Draft Tube

1. Base-

- The base is under the majority of the grinding machine. It is usually made of cast iron. This aids the rest of the grinding machine.

2.Table-

- The table is relaxed at the base. This is where the workpiece is placed and properly placed for grinding. It can move horizontally left and right using a traversing wheel known as a hand traversing wheel.

3.Column-

- It is a vertical column where the abrasive wheel, wheel head, and wheel guard are placed.

4. Abrasive Wheel-

- It is the main wheel that rotates and removes the material from the surface of the workpiece and makes it smooth. This wheel is coated with abrasion and allows the material to be removed easily from the surface of the workpiece.

5. Wheel Guard-

- It is a cover of an abrasive wheel or grinding wheel which protects the worker in any type of accident—grinding machine parts and functions.

6. Abrasive Wheel Head-

- It is a compartment that is moved up or down using a traversing wheel called a vertical feed handwheel. We push this wheel head forward so that the grinding wheel touches the workpiece.

7. Three Types of Traversing Wheels-

- Hand traversing wheel: – This traversings wheel is used to move the table, and it is left horizontally to accommodate the workpiece with the grinding wheel.

- Cross-side handwheel: – This traversing wheel is used to move the work table in the forward and backward direction to make contact between the workpiece and the grinding wheel.

- Vertical feed handwheel: – This traversing wheel is used to move the wheel head in vertical up and down direction. These three wheels are used to adjust the positions of the workpiece and the grinding wheel so that these two make contact with each other.

8. Coolant Supply Nozzle-

- The coolant supply nozzle is used to insert the nozzle into the grinding machine, which cools the work area so that heat is not decomposed into the workpiece and the abrasive wheel.

Also, Read: Simple Indexing in Milling Machine

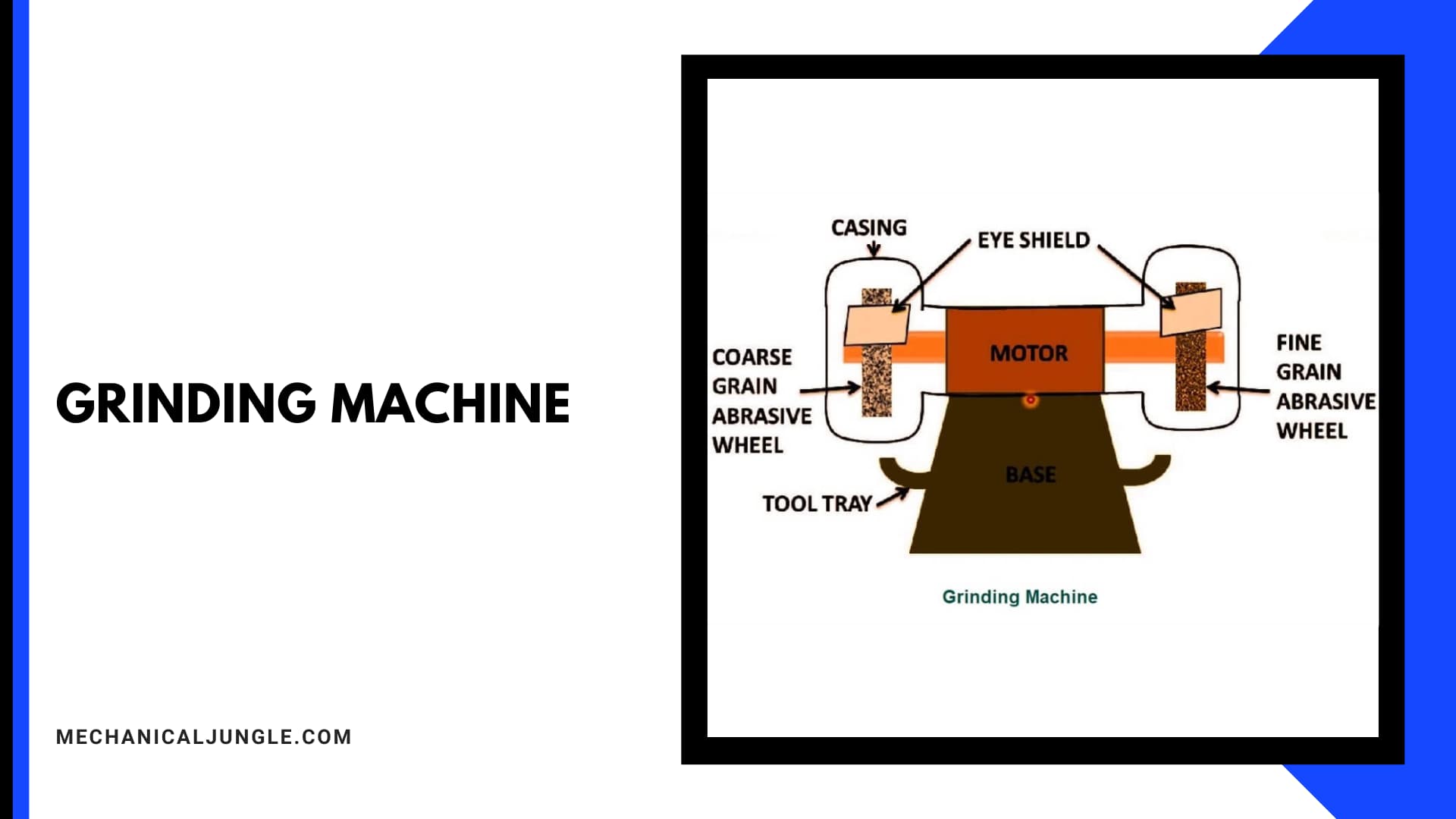

Grinding Machine:

- Grinding machines or grinders, often referred to as what is grinding machine, are devices that are used to grind workpieces. This produces a smooth finish on the flat surface. The grinding wheel is used in grinding machines for cutting.

- The grinding wheel is coated with friction material. Each grain of abrasive material is cut through a small piece of the workpiece through shear deformation.

- There are different types of grinding machines depending on the purposes.

Some of the most commonly used grindings machines are: –

- Surface Grinding Machine.

- Parts of Bench Grinder Machine.

- Cylindrical Grindings Machine.

The most commonly used of the three is the Surface grinding machine.

Grinding Machine Types:

Nine types of Grinding Machines:-

- Surface Grinding.

- Cylindrical Grinding.

- Centerless Grinding.

- Tool & Cutter Grinding.

- Jig Grinding.

- Gear Grinding.

- Centre Grinding.

- Die Grinding.

- Angle Grinding.

1. Surface Grinding–

- A surface grinder consists of an abrasives wheel, chucks (what is called the work holding device in surface grinding?), & a rotary table.

- The chuck is used to hold the materials while the wheel and object are rotated for a smooth finish.

2. Cylindrical Grinding–

- A cylindrical mill is used to shape the outside of the workpiece. These machines accept workpieces in many types of shapes as long as they can be rotated through the central axis.

- In a cylindrical mill, both the workpiece and the grinding wheel are rotated simultaneously.

- The outer diameter grinder, inner diameter grinder, and centerless grinder are all types of cylindrical grinders.

3. Centerless Grinding–

- A centerless grinder is the type of cylindrical grinder that uses two rotary wheels to secure the workpiece. Unlike a concentric grinder, a centerless grinder does not use a spindle.

- The rotation speed of the wheels determines the rate at which the material is removed.

4. Tool & Cutter Grinding–

- A tool and cutter mill uses a CNC machine tool with five axes and several grinding wheels.

- These tools are used for accelerating and producing drilling, endmills, and step tools such as milling cutters.

- It is also widely used in the woodworking and metal cutting industries to produce the necessary equipment.

5. Jig Grinding–

- Jig grinder, as the name suggests, there are many uses, dies, and fixtures when finishing jigs.

- Its primary function is to drill holes for grinding bushes and pins.

- It can also be used for the complex surface grinding to finish work started on a mill.

6. Gear Grinding–

- Gear-grinders are usually employed in the final machining process when manufacturing high-precision gears.

- The primary function of this machine is to remove the remainings few thousandths of an inch of materials left by other manufacturing methods (such as gassing or bobbing).

7. Centre Grinding–

- The center mill is usually employed as a machining process when all types of high-precision shafts are constructed. The primary function of this machine is to grind the centers of a shaft very accurately.

- Precise round center holes on both edges ensure a position with high repetition accuracy at live centers.

8. Die Grinding–

- The die grinder is a high-speed handheld rotary tool with a small diameter grind.

- They are typically driven by air (using compressed air) but can be run directly with a small electric motor or through a flexible shaft.

9. Angle Grinding–

- Another handheld power tool, is often used in construction and construction work.

Frequently Asked Questions (FAQ):

Parts of Grinder or Parts of a Grinder Machine

Parts and Functions of Grinding Machine with a grinding machine diagram:

- Base.

- Table.

- Column.

- Abrasive Wheel.

- Wheel Guard.

- Abrasive Wheel Head.

- Three Types of Traversing Wheels.

- Coolant Supply Nozzle.

Surface Grinder Parts

GCH Tool offers surface grinder replacement parts and components for Gardner, Giustina, Blanchard, Besly, Mattison, Brown & Sharp, and Okamoto grinders.

Grinding Machine Uses

Grinding machinery can be used to reduce the particulate size of various materials with precision, but is most commonly recognized for its uses in the mining industry where it is used to extract valuable metals, such as gold and silver, from surrounding host rock. These tools are not only useful but are also unique.

Types of Grinding Wheel

There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and use type 1 snagging wheels, type 27 grinding wheels, and type 28 grinding wheels.

Cylindrical Grinding Machines

As a global leader in grinding machine technology, Toyoda offers an extensive lineup of high-performance universal, cylindrical, camshaft, and crankshaft grinding machines. Originally designed for high-production automotive manufacturing, these grinders excel in the most demanding applications.

Tools Grinding Machine

Get the best deals on Tool Grinder when you shop the largest online … Enhanced 5C Universal Tool Cutter Grinder Machine W/5 Collets 5200RPM Sharpener.

Surface Grinder Uses

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a work piece, making its face of it flat or smooth.

Types of Grinders

- Angle Grinder.

- Bench Grinder.

- Belt Grinder.

- Wet Grinder.

- Die Grinder.

- Floor Grinder.

Grinding Process

Grinding is a machining process that’s used to remove material from a workpiece via a grinding wheel. As the grinding wheel turns, it cuts material off the workpiece while creating a smooth surface texture in the process.

Mechanical Grinding

A mechanical process using a rotating grinding wheel made from abrasive material containing small particles of grit ranging from fine to coarse. The wheel revolves around a central axis, making contact with the surface of the workpiece, while the particles act as cutting tools that cut chips from the material.

Types of Grinding

- Surface Grinding.

- Cylindrical Grinding.

- Centerless Grinding.

- Tool & Cutter Grinding.

- Jig Grinding.

- Gear grinding.

- Centre Grinding.

- Die Grinding.

- Angle Grinding.

Grinding Line

A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformation.

Like this post? Share it with your friends!

Suggested Read –

- Indexing Head

- Types of Grinders

- Cnc Machine Parts

- Milling Cutter Types

- Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

- What Is Magneto Ignition System | How Does an Ignition System Work | How Does a Magneto Work | What Does a Magneto Do | Magneto Ignition System

- What Is a Synchromesh Gearbox? | Principle of Synchromesh Gearbox | Construction of Synchromesh Gearbox | Working of Synchromesh Gearbox

- Working of Constant Mesh Gearbox | What Is a Constant Mesh Gearbox? | Different Gear Ratios in Constant Mesh Gearbox | Construction of Constant Mesh Gearbox

- What Is Cupola Furnace? | Cupola Furnace Design । Cupola Construction | Purpose of Cupola | Working Principle of Cupola Furnace: | Advantages of Cupola Furnace | Disadvantages of Cupola Furnace | Applications of Cupola Furnace