Important Point

What Is a Venturimeter?

- Venturi meters are used to measures the flow rate of a fluid through a pipe. This is an application of Bernoulli’s equation.

- Venturi meter theory works on the Bernoulli equation such that the velocity increases as the pressure decreases.

- Venturi meter theory G.B. Venturi in 1797, but it was first introduced in 1887 c, considered with Herschel’s help.

- This theory states that when the cross-sectional area of the flow decreases, a pressure difference between the different regions of the flow is created, and it helps to measure the difference under pressure.

- This pressure differential helps to measure the discharge inflow.

Working of Venturimeter:

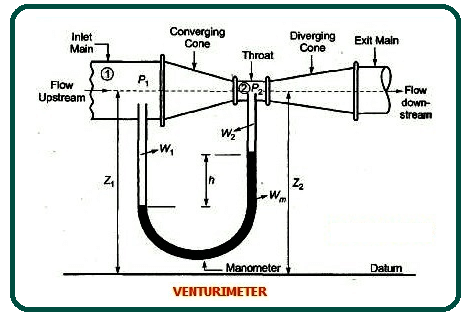

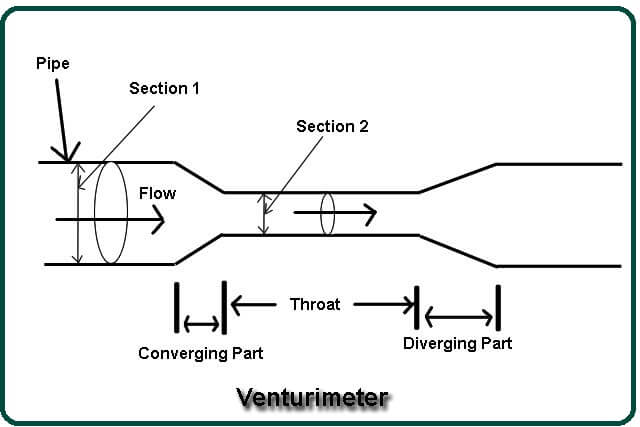

- The venturimeter works on the principle of Bernoulli’s equation, i.e., the pressure decreases as the velocity increases.

- The cross-section of the throat is less than the cross-section of the inlet pipe.

- As the cross-section from the inlet pipe to the throat decreases, the velocity of the fluid increases, and hence the pressure decreases.

- Due to the decrease in pressure, a pressure difference is created between the inlet pipe and the venturimet’s throat.

- This pressure difference can be measured by applying a differential manometer between the inlet section and throat section or using two gauges on the inlet section and throat.

- The pressure difference through the pipe is calculated after obtaining the flow rate.

Construction of Venturimeter:

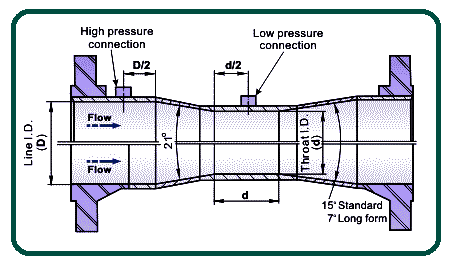

- As stated above, it consists of three parts, the part of the larynx and the deviation. These three parts are arranged in a systematic order. The first is an inlet section or converging section.

- This is the area where the cross-section emerges in a conical shape for contact with the throat region. In this section, the cross-section area decreases from beginning to end.

- This section is connected by an inlet pipe at one end and a cylindrical throat at the other end. The angle of convergence is typically 20–22 °. the other is a cylindrical larynx.

- This is the central part of the venturimeter. It is a cylindrical pipe in the ventimeter through which the fluid passes after converting to the convergence section.

- The throat usually has a diameter of the throat that is half the diameter of the pipe. The throat diameter remains the same through its length. The last one is turning the section.

- This is the end of the ventimeter. On one side, it is connected to the throat of the venturimeter, and on the other side is attached to the pipe.

- The divergent section has an angle of 5 to 15 degrees. The deviation angle is less than the convergence angle because the length of the deviation cone is larger than the convergence cone. The main reason for the small deviation angle is to avoid isolation of the flow from the walls.

The Expression for the Rate of Flow-Through Venturimeter:

Consider a venturimeter is fitted in a horizontals pipe through which fluid ( water ) is flowing, as shown in the figure below.

Let,

a1 = cross-section area of the inlet pipe

d1 = diameter of the inlet pipe

v1 = velocity at the inlet pipe

p1 = pressure at the inlet pipe

also,

a2 = cross-section area of the throat

d2 = diameter of the throat

v2 = velocity at the throat

p2 = pressure at inlet throat

d1, p1, v1, and a1 are the diameters at the inlet, the pressure at the inlet, the velocity at the inlet, and the area at cross-section 1.

And d2, p2, v2, and a2 are the corresponding values in section 2.

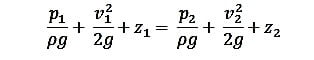

Applying Bernoulli’s equations in sections 1 and 2

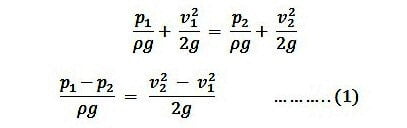

As the pipe is Horizontals, so z1 = z2

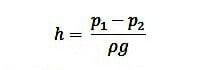

Therefore (P1 – P2)/ρg is the difference of pressure heads at sections 1 and 2, and it is equal to h. so

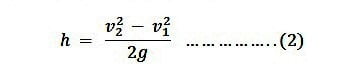

Substituting these values of h in equation (1), we get

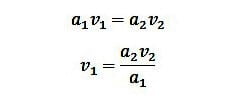

Now applying continuity equations at section 1 and 2

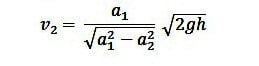

Substituting this value of v1 in equations (2) and solving, we get

Discharge

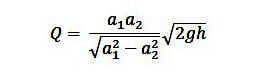

Substitutions the value of v2 in the above equation

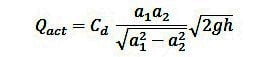

Q is the theoretical discharges under ideal conditions. The actual discharge will be less than the theoretical discharge. The actual discharges are given by the formula.

Where Cd is the coefficients of the venturimeter, and its value is less than 1.

Also, Read: Parts of Shaper Machine | What Is the Shaper Machine? | Working of Shaper Machine

Disadvantages of Venturimeter:

- The installation cost of a venturi meter is high.

- There are some difficulties during maintenance.

- This device cannot be used where the pipe has a small diameter of 76.2 mm. Non-linear.

- This system occupies more space than the orifice meter.

- This is the lower Reynolds number limit of 150,000.

- It is expensive and a bit heavy.

So, this is all about the venturimeter. I hope you will understand the concept of venturi meter and also be able to understand how it works. If you liked this stuff, then don’t forget to share this article on your favorite social media platforms.

Advantages of Venturimeter:

The advantages of a Venturimeter are as follows.

- The power loss is very less.

- It can be used where a small head is available.

- High reproducibility (to the extent of consistently achieving results when an experiment is repeated).

- Accuracy is greater in wide flow ranges.

- It can also be used for compressed and incompatible fluid.

- This device is easy to operate.

- The coefficient of discharge (CD) is higher for the venturi meter.

- It is widely used for high flow rate (discharge).

Applications of Venturimeter:

Applications of Venturimeter are as follows.

- Calculating the flow rate of liquids that are discharged through pipes.

- In the industrial sector, it is used to determine the pressure of the volume of gas and liquid inside a pipe.

- The flow of chemicals in pipelines.

- It is widely used in the waste treatment process, where larger diameter pipes are used.

- It is also used in the medical field to measure the rate of blood flow in the arteries.

- It is also used where high-pressure recovery is required.

Frequently Asked Questions (FAQ)

What Is a Venturimeter?

A venturi is a device that can be used to measure the flow of fluid in a pipe. The fluid flow rate can also be increased by using a venturi.

Venturimeter

Venturimeter is a type of flowmeter that works on the principle of Bernoulli’s Equation. This device is widely used in the water, chemical, pharmaceutical, and oil & gas industries to measure the flow rates of fluids inside a pipe.

Venturimeter Is Used for Measuring

A Venturi meter is a device that is used for measuring the speed of a fluid within a pipe. The drawing shows a gas flowing at speed υ2 through a horizontal section of pipe whose cross-sectional area is A2 = 0.0700 m2.

Venturimeter Working Principle

The venturi meter works on the principle of Bernoulli’s equation, i.e., the pressure decreases as the velocity increases. The cross-section of the throat is less than the cross-section of the inlet pipe.

Advantages of Venturimeter

Advantages

- High-pressure recovery. Low permanent pressure drop.

- High coefficient of discharge.

- Smooth construction and low cone angle help solid particles flow through it.

- It can be installed in any direction, horizontal, vertical, and inclined.

- More accurate than orifice and flow nozzle.

Applications of Venturimeter

Applications

- Used in Engine Carburetors (Automobile Sector) to measure airflow.

- Process industries (Process and Power Piping Industries) are used to measure and control process flow.

- In the medical industry, blood flow in the arteries is measured by centimeters.

Like this post? Share it with your friends!

Suggested Read –

- Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining

- Parts of Shaper Machine | What Is the Shaper Machine? | Working of Shaper Machine

- What Is a Synchromesh Gearbox? | Principle of Synchromesh Gearbox | Construction of Synchromesh Gearbox | Working of Synchromesh Gearbox

- Working of Constant Mesh Gearbox | What Is a Constant Mesh Gearbox? | Different Gear Ratios in Constant Mesh Gearbox | Construction of Constant Mesh Gearbox

- What Is Magneto Ignition System | How Does an Ignition System Work | How Does a Magneto Work | What Does a Magneto Do | Magneto Ignition System