Important Point

What Is a Hacksaw?

Hacksaw is hand-operated, used for cutting small toothed metal pipes, rods, brackets, etc. Huxos can also cut through the plastic. The hacksaw has a U-shaped frame & a handle at one end. Hacksaws have smalls pins at each end of the frame that receives a blade.

A tensioner nut or knobs is then used to extend the length of the frame, which puts tension on the blade & locks it in place. The blade can be installed for cutting on push or pull strokes; Cutting is more common on push strokes.

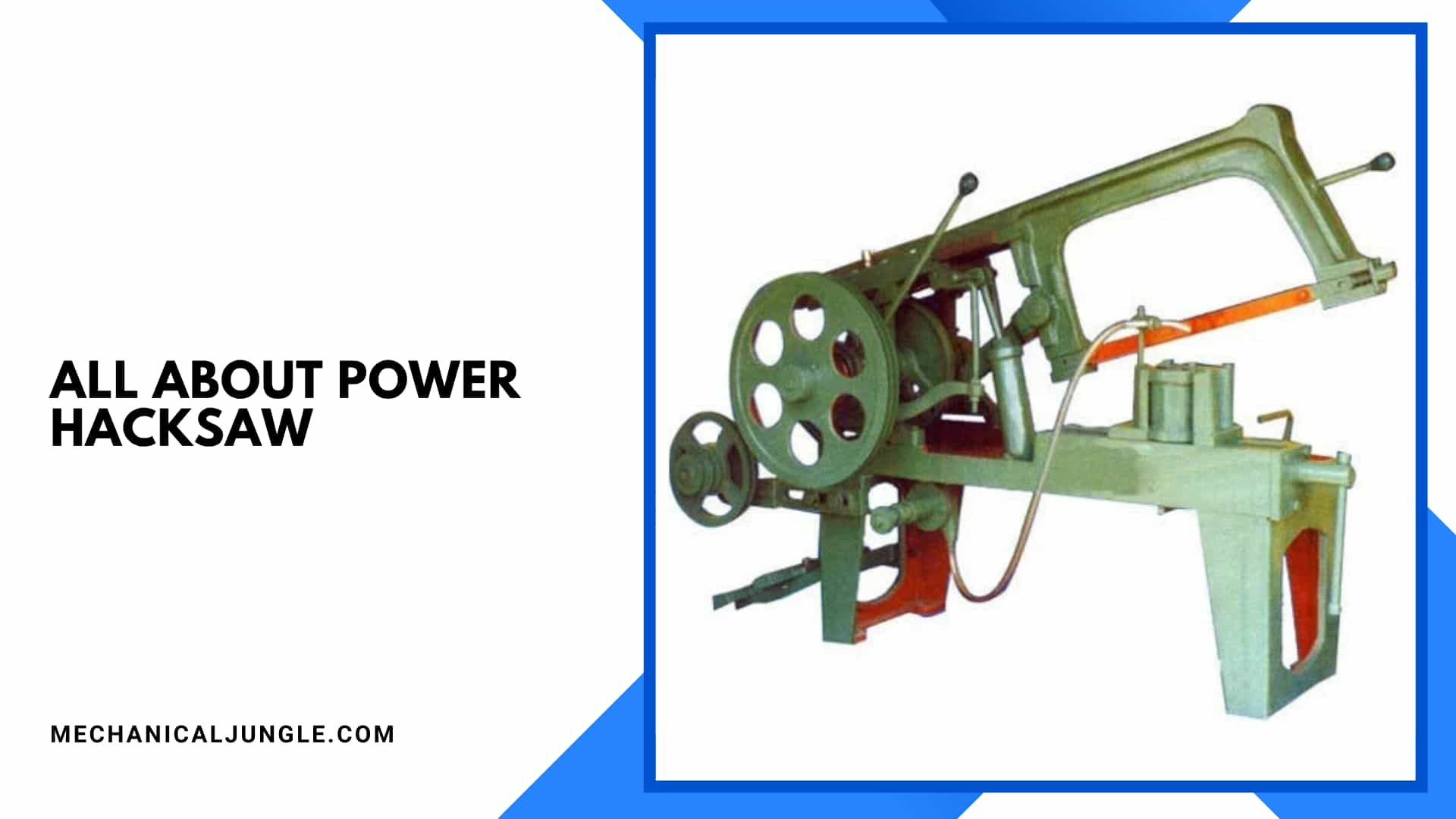

When a hacksaw is operated using machines, it is known as a power hacksaw. It is a type of rotating saw machine. Power hacksaw is used when materials cannot be cut to hack by hand.

When the cutting diameters of the material to be cut are large, it is very difficult to cut with a hand-cut hacksaw, in which case power hacksaws are used. Power hacks can cut large diameter or workpiece workpieces that require a large amount of time & hard work to cut.

This machine can be used to cut any type of material in workshops as the hacksaw blade used is made of HSS (high-speed). Some cutting fluids are provided in this machine to cut hard materials.

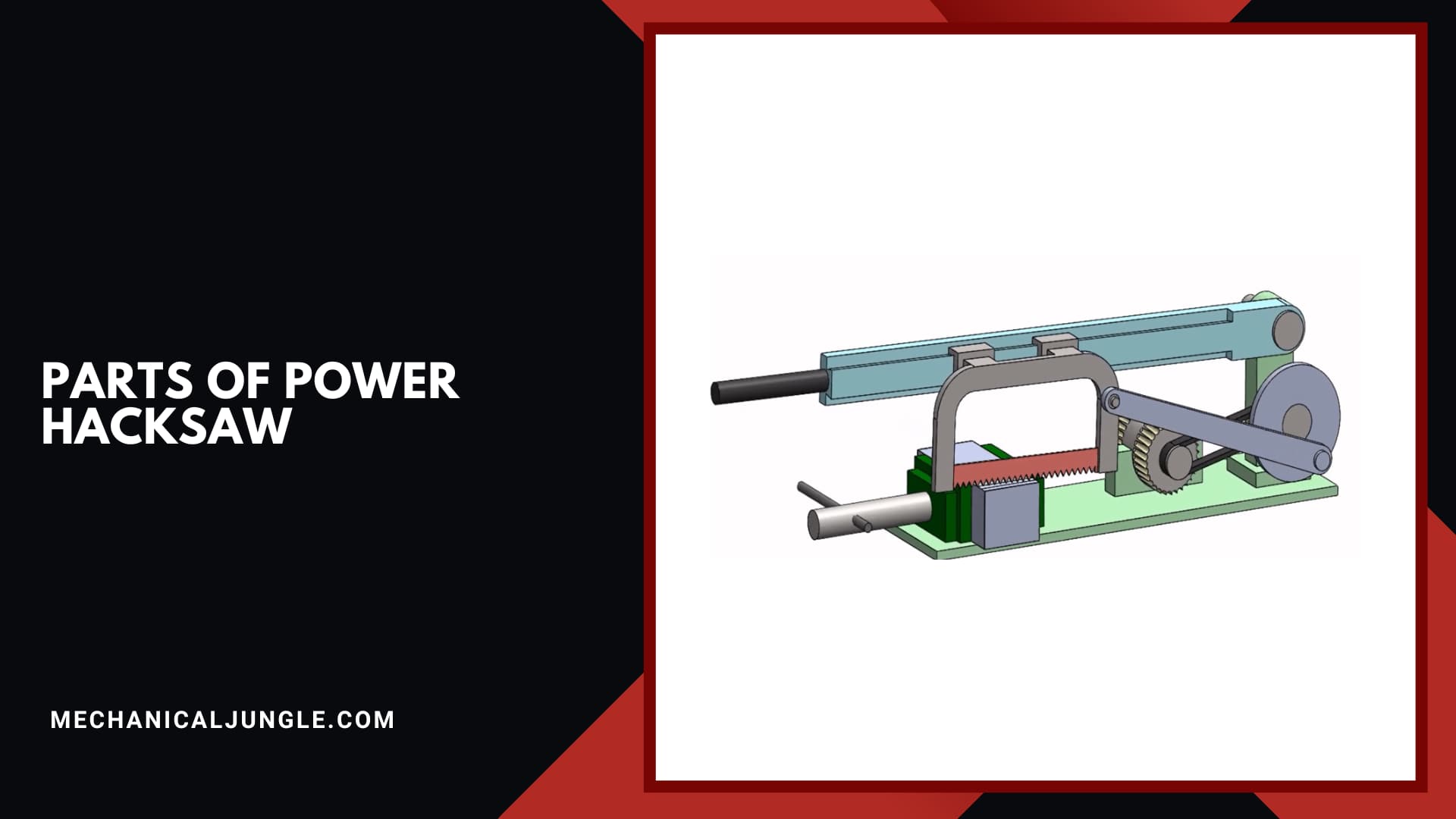

Parts of Power Hacksaw:

#1. Base

The base of the power hacksaws is made using cast products. All the other parts of the power hacksaws are carried by this base.

#2. Column

The first part of the powers hacksaw is the columns. This column is a housing for the drivings mechanism of the power hacksaws, & the electrical cables are also present inside this column.

#3. ON/OFF Switch

These switches are used on and off. These devices are connected to an electrical connection & can be switched on and off using these switches.

#4. Support

In front of the column, there is two support, one is horizontals support, and another one is verticals support. The vertical supports the horizontals frame or support.

#5. Machine Vice

Machine Vice is present above the horizontals support. This machine’s vice is used to clamp the workpiece, i.e., hold the workpieces tightly. These vices are adjustable so that various sizes & shapes of metals can be held.

This machine’s vice has been handled. The vices can be tightened or loosened by turnings the handles. This vice locks the workpiece & does not allow it to move during the cutting operation. The size of the power hacksaws is determined by the largest workpiece that can be held in the vice.

#6. Cooling Pipe

Cooling pipe is used to provides coolant while cutting so that too much heat is not produced during cutting & the hacksaw blade does not get blunt. These cooling pipes provide a coolant between the hacksaw & the workpiece. These cooling pipes provide the coolant by the application of a pump.

#7. Power Hacksaw Frame

The power hacksaw frames are used to support & carry the hacksaw blade. The power hacksaw frames are connected to the driving mechanism present inside the columns. These frames are also known as an arm. The hacksaw blade is fixed in this armor frame.

#8. Handwheel

The handwheels are present on the top of the handle & are rotated to move the hacksaw frame up and down.

#9. Emergency Foot Switch

Almost every power hacksaw has an emergency footswitch to turn the power hacksaw on and off. This is added mainly to turn off the machine in emergency conditions. This footswitch is located on the front side of the machine.

#10. Hacksaw Blade (Cutting Blade)

The hacksaw blade performs the cuttings operation on the workpiece. The blade does cuttings in the forward stroke & removes chip produced while cutting in the backward strokes. The blade of this hacksaws blade is made up of high-speed steel. Blades of power hacksaws are categorized based on the materials from which they are made and the number of teeth in the blades per inch.

The top category blade is made from High-Speed Steel (HH.S.S. But HH.S.S.blades are very expensive, so there are cheaper alternatives like carbon steels blade.

Generally, the number of teeth per inch varied from 14 to 24; as the number of teeth increases, the smoothness of cuttings also increases. The correct blade for a particulars workpiece is determined based on the material to be cut.

#11. Handle

A handle is attached to the column. These handles are used to move the hacksaw frame & hence the hacksaw blade up and downs. Hacksaw blades are moved near the workpiece to performs the cutting operations.

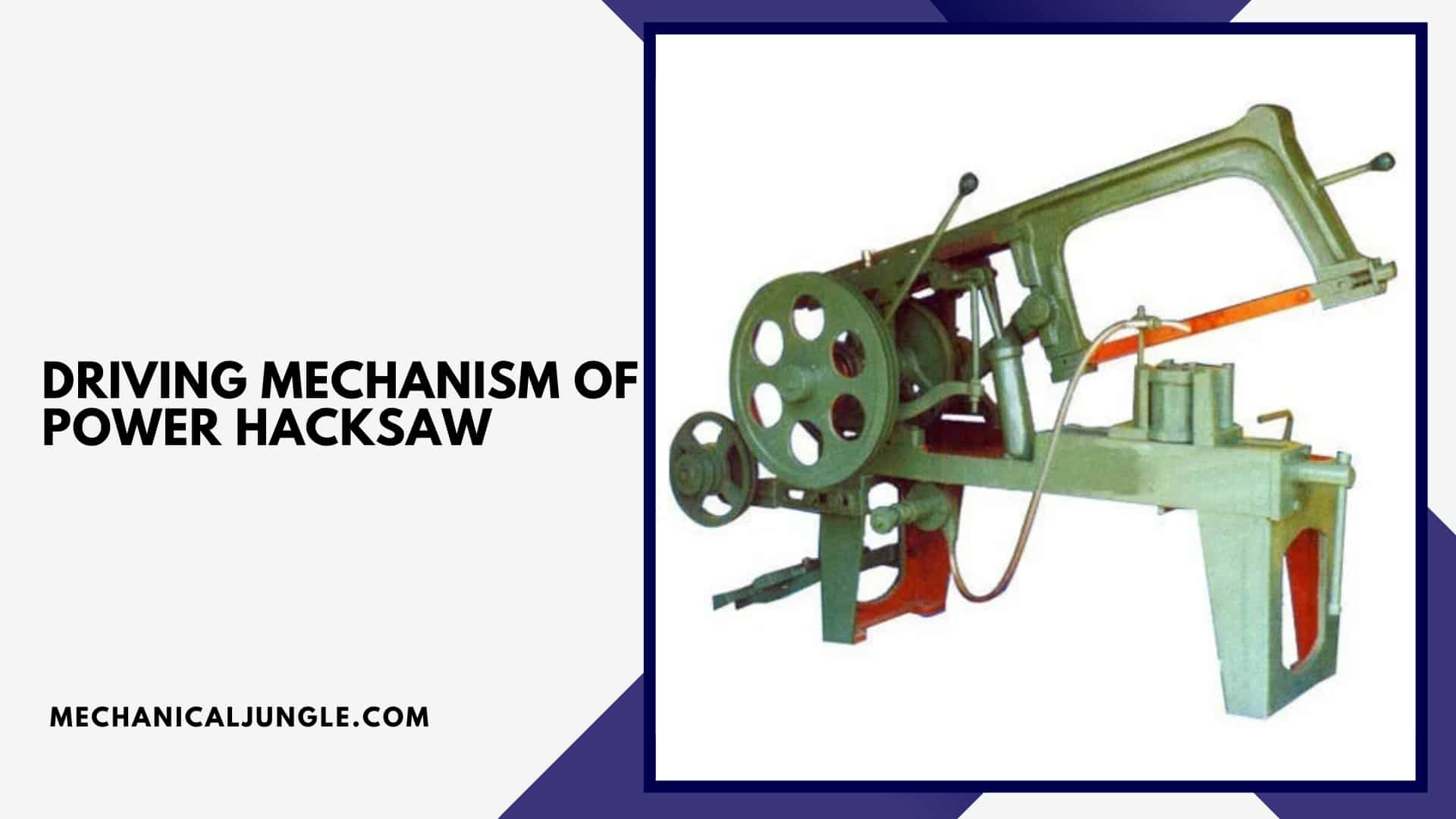

Driving Mechanism of Power Hacksaw:

Two pulleys are placed on fronts of each other. One winch is on top of another. These two pulleys are connected by a belt. A link is attached to the pulley at the top. The link is connected to a pulley on one side and an electric hacksaw frame on the other side.

When the power hacksaws are switched on, the bottom pulley starts rotating, and since this lower pulley is connected to the top pulleys by a belt, the top pulley also starts rotating.

When the top pulley rotates, the link connected to the top pulley will also rotate. Since this link is connected to the power hacksaw frame, when the link moves back and forth due to the pulley rotating, the power hacksaw frame will also move forward and backwards. The rotational speed of the pulley will be converted into reciprocating motion in the power hacksaw frame.

So in this way, the driving mechanism of an electric hacksaw works. We can increase or decrease the speed of the pulley, and the feed of the forward and backward strokes can be adjusted into a power hacksaw.

The speed of the pulleys can be changed by changing the belt from one size pulley to another shaped pulley. If the belt is placed on a small pulley, the speed increases, and if the belt is placed on a larger pulley, the cutting speed decreases. Different types of metals can be observed at the proper speed by the change of speed.

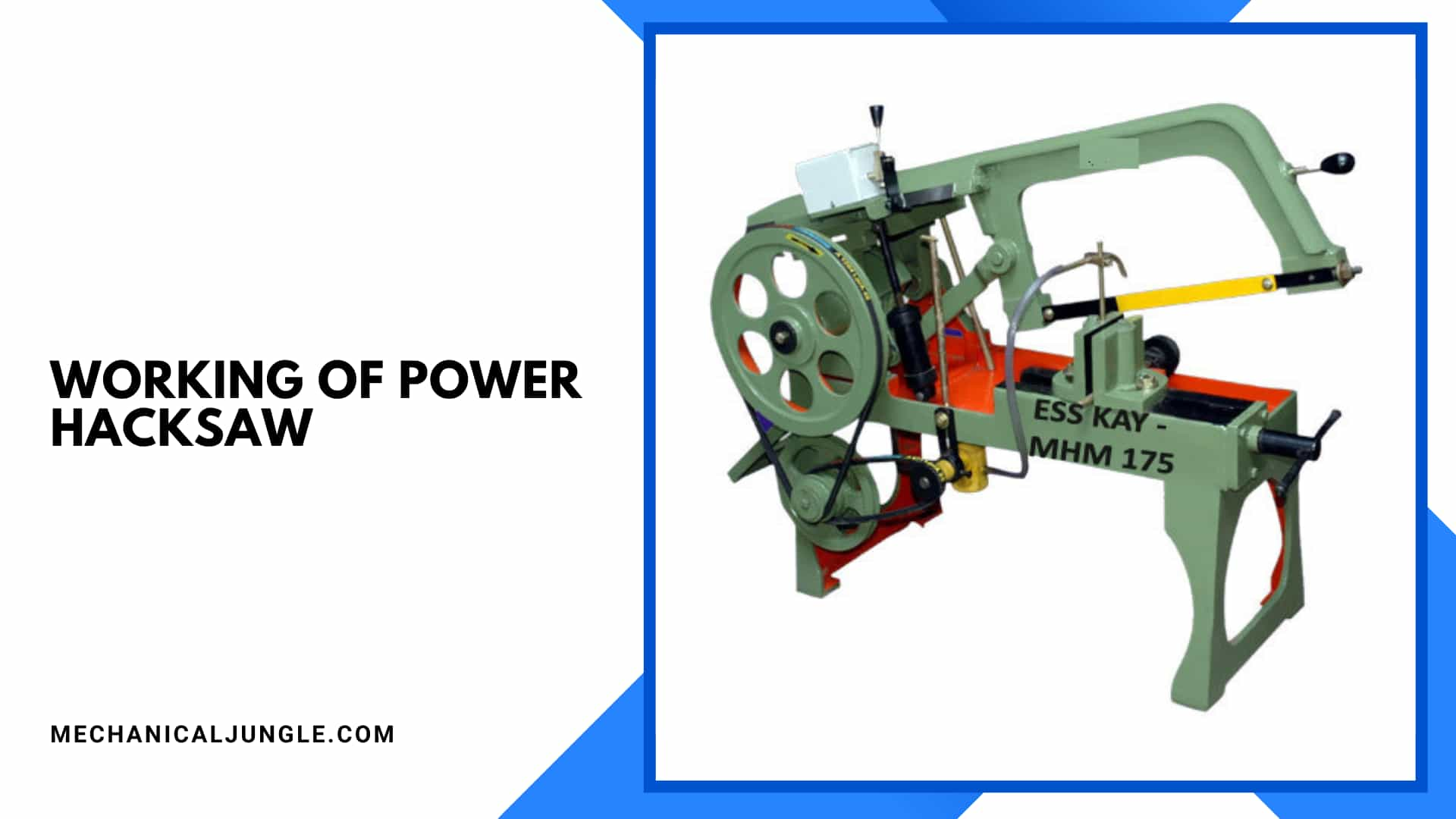

Working of Power Hacksaw:

The vice of the machine has two jaws. One jaw is stable, and the other is flammable. There is a threaded row that is attached to the movable jaw on one side and a handle on the other side. When we rotate this handle, the movable jaws of the machine vice move forward and backwards on this threaded rod of the machine vice.

We can easily attach any workpiece in the vice of this machine to use movable. The cooling pipe then supplies the coolant during the cutting process between the hacksaw and the workpiece.

This coolant extends tool life, helps remove chips and removes heat generated during cutting, and keeps equipment and workpiece cool. This coolant acts as a lubricant to smooth the cutting process.

The hacksaw moves along the blade frame using the driving mechanism of the power hacksaw present inside the front and rear columns.

When the hacksaw blade is brought near the workpiece, and the switch is switched on. The driving mechanism begins, and the cutting process or the process of removing material from the workpiece.

A forward stroke of a power hacksaw is a cutting stroke that consists of a material removal process, and a backward stroke is a passive stroke. Cutting only during the forward stroke avoids unnecessary wear on the saw blade.

A backward stroke is used to extract chips from the workpiece produced during the forward stroke.

Frequently Asked Questions (FAQ)

Power Hacksaws

Power hacksaws are often used to cut large pipes, steel, cast iron and other hard materials. The straight blade is attached to the tool and moves back and forth across the workpiece to make the cut. Power hacksaws have a slower speed and longer stroke length than reciprocating saws, which slows the cutting speed but leaves a finer edge.

Hacksaw Parts

Following are the main two parts of a hacksaw:

- Base

- Column

- ON/OFF Switch

- Support

- Machine Vice

- Cooling Pipe

- Power Hacksaw Frame

- Handwheel

- Emergency Foot Switch

- Hacksaw Blade (Cutting Blade)

- Handle

What Is a Hacksaw?

A hacksaw is a handheld, small-toothed saw used to cut metal pipes, rods, brackets, etc. Hacksaws can also cut through the plastic. The hacksaw has a U-shaped frame and a handle at one end. There are small pins on each end of the hacksaw’s frame that receive a blade.

Small Hack Saw

Small Hacksaws easily fit in your toolbox or in limited spaces and are great for making fast cuts in small pieces of metal, wood and plastic – such as a metal rod, a block of wood or PVC tubing.

Electric Hack Saw

Power hacksaws offer a range of options for portable cutting of pipe, structural steel, tanks and other materials. The rechargeable electric saw is light and portable, long battery life, and will not damage the bark. This is a professional electric hacksaw tool. Electric hacksaw adopts high-quality tungsten steel material, durable and wear-resistant.

Best Power Hacksaw for Industrial Cutting

When it comes to power hacksaws for industrial cutting, there are several reputable brands and models to consider. Here are a few top options:

- Dewalt DWM120K: The Dewalt DWM120K is a popular choice known for its durability and cutting performance. It features a powerful motor, adjustable speed control, and a compact design that allows for easy maneuverability.

- Milwaukee 6232-21: The Milwaukee 6232-21 is another excellent power hacksaw designed for industrial use. It offers a high cutting capacity, a sturdy construction, and a variable speed trigger for precise control.

- Makita LC1230: The Makita LC1230 is a reliable and efficient power hacksaw suitable for heavy-duty cutting applications. It boasts a large cutting capacity, a quick-release vise for fast material changes, and a durable build.

- Jet 414220: The Jet 414220 is a heavy-duty power hacksaw built for industrial cutting tasks. It features a powerful motor, adjustable blade speeds, and a rugged construction that can withstand demanding environments.

- Evolution Power Tools EVOSAW380: The Evolution EVOSAW380 is a versatile power hacksaw that excels at cutting metal. It utilizes a cold-cutting technology, reducing heat and burrs, and has a strong motor and a large cutting capacity.

Power Hacksaw Machine for Sale

As an AI language model, I don’t have real-time information on specific products or their availability. However, there are several avenues where you can find power hacksaw machines for sale. Here are some options to consider:

- Online marketplaces: Websites like Amazon, eBay, and Alibaba often have a wide range of power hacksaw machines available for purchase. You can browse through their listings, compare prices, and read customer reviews to make an informed decision.

- Industrial machinery suppliers: Companies specializing in industrial machinery and equipment, both online and offline, may have power hacksaw machines for sale. You can search for suppliers in your local area or explore online catalogs of machinery suppliers.

- Auctions and second-hand markets: Machinery auctions or second-hand markets can be a great way to find used power hacksaw machines at a lower cost. Check local classified ads, online auction websites, or visit local industrial equipment auctions to find potential deals.

- Manufacturer websites: Many power hacksaw machine manufacturers have their own websites where they showcase their product range and provide information about authorized distributors or dealers. You can visit the websites of specific manufacturers to find out where their machines are available for purchase.

Affordable Power Hacksaw Blades

When looking for affordable power hacksaw blades, there are a few options you can consider:

- Generic/Aftermarket Blades: Generic or aftermarket blades are often more affordable compared to blades from specific brands. These blades are designed to fit a range of power hacksaws and can offer decent performance at a lower cost. You can find these blades online or at local industrial supply stores.

- Bulk Purchases: Buying power hacksaw blades in bulk can often lead to cost savings. Many suppliers offer discounted prices for larger quantities. If you frequently use power hacksaws and require a significant number of blades, purchasing in bulk can be a cost-effective option.

- Local Suppliers: Check with local industrial supply stores or hardware stores that specialize in tools and equipment. They may have a selection of power hacksaw blades at competitive prices. Visiting these stores in person or contacting them directly can help you find affordable options.

- Online Marketplaces: Websites like Amazon, eBay, or other online industrial supply stores often offer a wide range of power hacksaw blades at different price points. You can compare prices from various sellers and find affordable options that suit your budget.

- Sales and Discounts: Keep an eye out for sales, promotions, or special discounts offered by suppliers or manufacturers. They may periodically offer discounted prices on power hacksaw blades, allowing you to purchase them at a more affordable rate.

Benefits of Using a Power Hacksaw

It is highly effective at cutting large pieces of metal despite having somewhat archaic technology. The development of the power hacksaw enhanced the basic hand-held hacksaw’s capabilities. Compared to what a hand-held hacksaw can handle, it can cut through thicker and broader materials.

Power hacksaw vs. bandsaw: Which is more efficient?

Efficiency. There is no question that the bandsaw is far more effective than the motorized hacksaw in terms of efficiency. The speed at which the bandsaw cuts and its precision and cleanliness contribute to this. Compared to using a powered hacksaw, projects take less time to finish.

Parts of Hacksaw and Their Functions

The hacksaw has a U-shaped frame and a handle at one end. Hacksaws have small pins at each end of the frame that receive a blade. A tensioner nut or knob is then used to extend the length of the frame, which puts tension on the blade and locks it in place.

Types of Power Hacksaw Machine

- Hacksaw Machines.

- Horizontal Swing Type Bandsaw (B250 HDHL DA)

- Double Column Bandsaw Machine.

Uses of Hacksaw in Workshop

What a Hacksaw Is Used For. A hacksaw is mainly used for cutting thin metal such as aluminum, brass, steel, or copper. Hacksaws are also used for cutting plastics such as PVC, PEX, or ABS on pipes or on sheet goods made of PVC, polystyrene, and more.

How to Use a Hacksaw Safely?

- Select correct blade for material being cut.

- Secure blade with the teeth pointing forward.

- Keep blade rigid, and frame properly aligned.

- Cut using steady strokes, directed away from you.

- Use entire length of blade in each cutting stroke.

Like this post? Share it with your friends!

Suggested Read –

- Cutting Fluids

- Parts and Functions of Grinding Machine | Grinding Machine | Grinding Machine Types

- Parts of Cornish Boiler | Working Principle of Cornish Boiler | Construction of Cornish Boiler

- Parts of Air Lift Pump | Working Principle of Air Lift Pump | Advantages of Air Lift Pump | Disadvantages of Air Lift Pump

- Pattern Allowances In Casting | Why the Pattern Allowances In Casting Affected | Finishing or Machining Allowance | Shake or Rapping Allowance

- Difference Between Air Conditioning and Refrigeration Why We Need a Refrigeration | Refrigeration System | Refrigeration Cycle | Principle of Refrigeration